I. Four Core Advantages of Vigorous Twin Screw Multiphase Pumps

- Super Adaptability: Unafraid of Big Gas – Liquid – Solid Ratio Changes

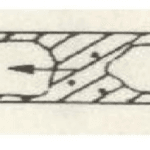

Use twin – screw non – contact design, handle 100% gas – volume fraction.

Have strong dynamic adjustment, keep stable flow when conditions change, avoid centrifugal pump issues. - Transport Stability: Ensure Precision for Industrial Processes

Mesh equal – pitch screws with precision bushings for near – zero – pulsation flow.

Pressure fluctuation within ≤ ±1%.

Typical Case: In a chemical plant’s polymerization, boost three – phase transport pressure stability by 90%, raise reaction efficiency by 15%. - Energy – saving & High – efficiency: Revolution for Cost – down & Efficiency – up

Optimized flow – channel gets 98% volumetric efficiency, save over 30% energy vs traditional pumps.

Use variable – frequency speed – regulation for “on – demand energy”, cut annual energy cost by over 500,000 yuan in offshore project. - An offshore platform uses Vigorous twin – screw pumps instead of old “separator + multi – pump” system.

Transport gas – containing crude (60% gas – liquid ratio) and sand mixture.

Achievements: Cut equipment space by 60%, reduce investment cost by 45%, save over 2 million yuan in annual maintenance.

Technical Highlights: Install internal gas – liquid mixer to stop slug flow, avoid pipeline vibration. - Case 2: High – viscosity Heavy – Oil Exploitation – Breaking Flow Limit

A Xinjiang heavy – oil field (viscosity > 50,000 cP) uses twin – screw pumps for integrated oil lifting.

Achievements: Lower wellhead back – pressure by 30%, increase daily oil production by 15%, cut separation equipment energy by 40%.

Technical Highlights: Custom high – temperature hardened screws for 120℃ downhole, self – cleaning flow – channel to prevent coking. - Wear – resistant & Long – lasting: Durability in Extreme Conditions

Screws with tungsten carbide coating, extend wear – resistant life 3 times.

In 20% sand – content heavy – oil mining, run 20,000 hours without major repair, cut maintenance cost by 70%.

II. Industry Benchmark Cases: Twin – Screw Pumps Breaking Tradition

- Case 1: Offshore Oil Platform – Space & Cost Optimization

- An offshore platform uses Vigorous twin – screw pumps instead of old “separator + multi – pump” system.

Transport gas – containing crude (60% gas – liquid ratio) and sand mixture.

Achievements: Cut equipment space by 60%, reduce investment cost by 45%, save over 2 million yuan in annual maintenance.

Technical Highlights: Install internal gas – liquid mixer to stop slug flow, avoid pipeline vibration. - Case 2: High – viscosity Heavy – Oil Exploitation – Breaking Flow Limit

A Xinjiang heavy – oil field (viscosity > 50,000 cP) uses twin – screw pumps for integrated oil lifting.

Achievements: Lower wellhead back – pressure by 30%, increase daily oil production by 15%, cut separation equipment energy by 40%.

Technical Highlights: Custom high – temperature hardened screws for 120℃ downhole, self – cleaning flow – channel to prevent coking.

III. Why Choose Vigorous Twin – Screw Multiphase Pumps?

- Full – cycle Cost Optimization: Offer custom solutions from design to intelligent maintenance.

- Globally Proven Reliability: Over 500 devices work well from – 40℃ to 180℃.

- Quick – response Service: 24 – hour tech support + local spares, keep downtime < 8 hours.

Conclusion: Transportation Innovation towards Industry 4.0

With smart production growth, Vigorous pumps re – define multiphase fluid transport via IoT and predictive maintenance.

Good for cost – down, efficiency – up and energy – consumption challenges.

Contact Vigorous engineers for your custom solution now!