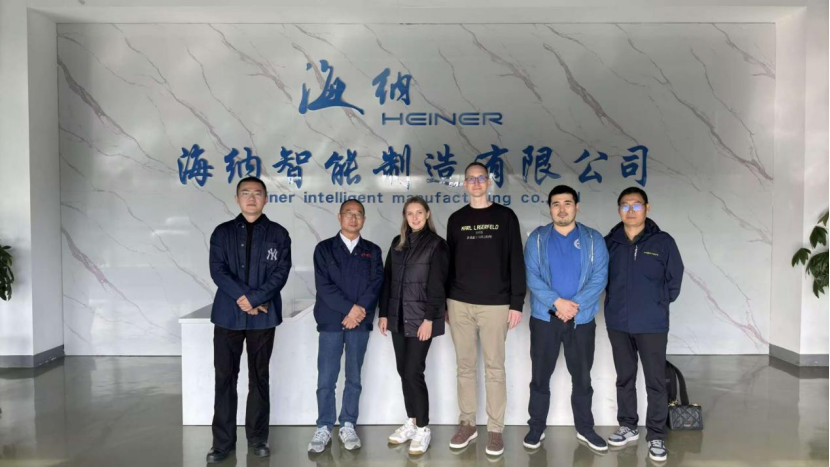

Recently, foreign customers Fedor, Nurbek, Irina, on behalf of Shanghai Gelai Supply Chain Management Co., Ltd., a subsidiary of Gazprom Engineering Company, visited and inspected the factory of Huangshan Vigor Pump Co., Ltd.

During this period, the foreign team also expressed the main purpose and needs of this visit, that is, to understand the production and manufacturing process of our factory, verify the production and manufacturing capabilities of our factory, and understand the main business and product types of our factory. At the same time, Nurbek and his team showed great interest in the natural gas booster transmission device.

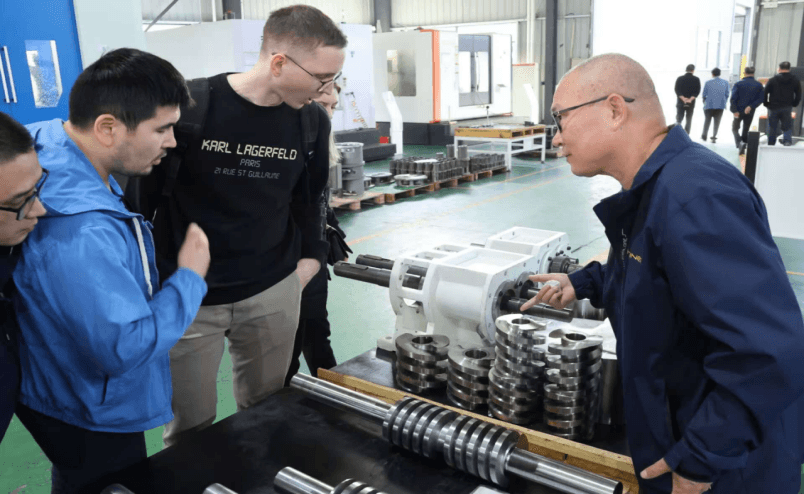

Chief Engineer Chen Rui introduced the integrated forged screw of Vigor Pump Industry, the patented profile used in the screw, and the improvement of pump efficiency brought by this unique profile. The two sides asked and answered questions about the strength and service life of the integrated forged screw shaft, the matching between the screws, and the hardening treatment of the screw surface.

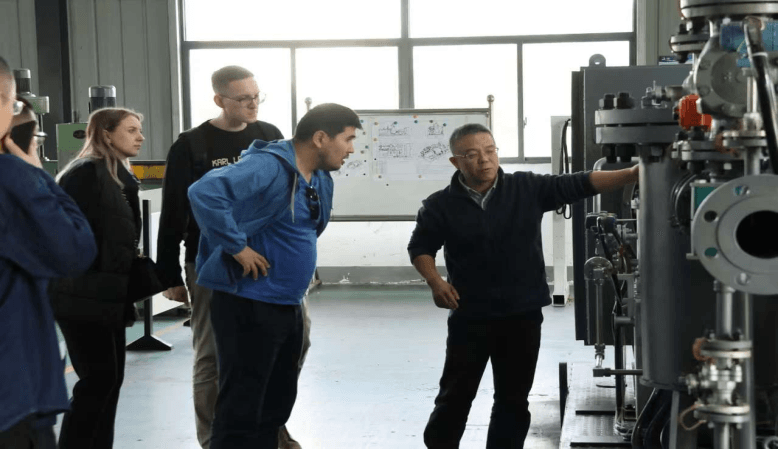

Then, Production Director Cheng Cuifeng introduced the specific processing process of the screw pump to the Russian team in the Metalworking Workshop No. 2. The two sides visited the horizontal machining center, vertical machining center, CNC lathe and other production equipment in the metalworking workshop No. 2 in turn, and inspected the actual processing of bushings, bearing seats, screw rotors and other parts. During this period, Cheng Cuifeng, the production director, supplemented the process flow of our factory’s casting workpieces and raw material inspection. In addition, the group also visited the multiphase booster and drainage device for natural gas wells newly developed by our factory.

In the Weigeshi Pump Industry Laboratory, the technicians demonstrated to everyone how to use a spectrometer to detect the components of raw materials, use a Vickers hardness tester to check the strength of raw materials, and use an ultrasonic flaw detector to perform non-destructive testing on welded pump bodies and parts. In terms of selecting raw materials, Weigeshi has a set of strict acceptance standards. The technicians also demonstrated the use of 3D scanners and three-coordinate devices to collect and inspect the error data of processed workpieces to ensure the quality of the products.

Next, the two sides came to the assembly workshop and test bench to understand the assembly and testing process of the screw pump. After watching the staff assemble, the visiting team came to the test bench. In the integrated control room of the test station, everyone can see the various data and actual test status of the screw pump being tested through the computer. These test data and live videos can be sent to customers in real time through the Internet, so that customers can use them with peace of mind.

Finally, the two sides returned to the conference room to summarize the visit. Gazprom Engineering Company expressed its affirmation and trust in the work of our factory and hoped that through this visit, the exchanges and cooperation between the two sides could be further deepened.