Description

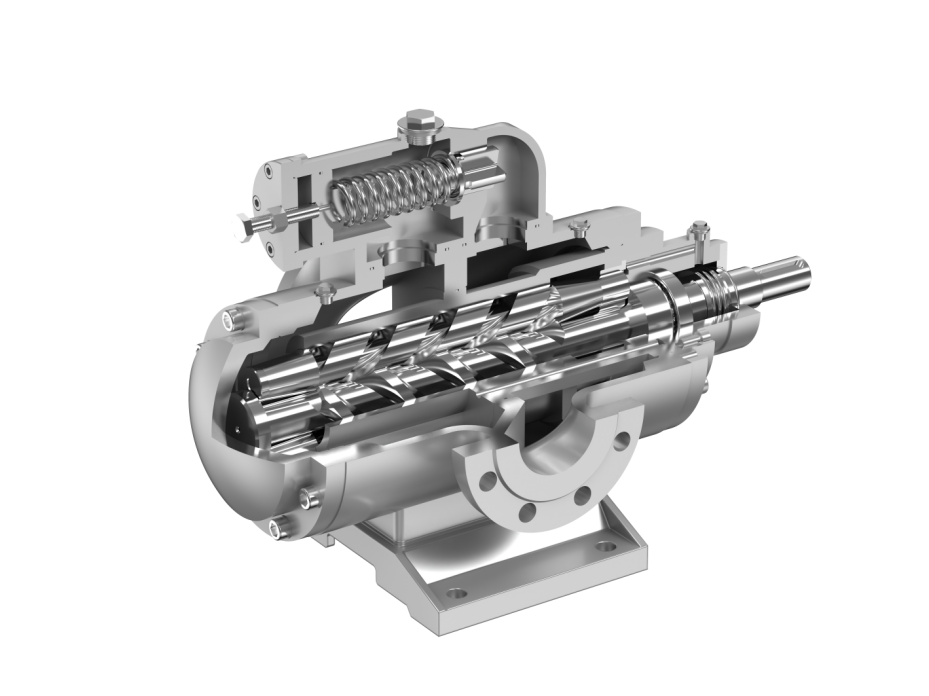

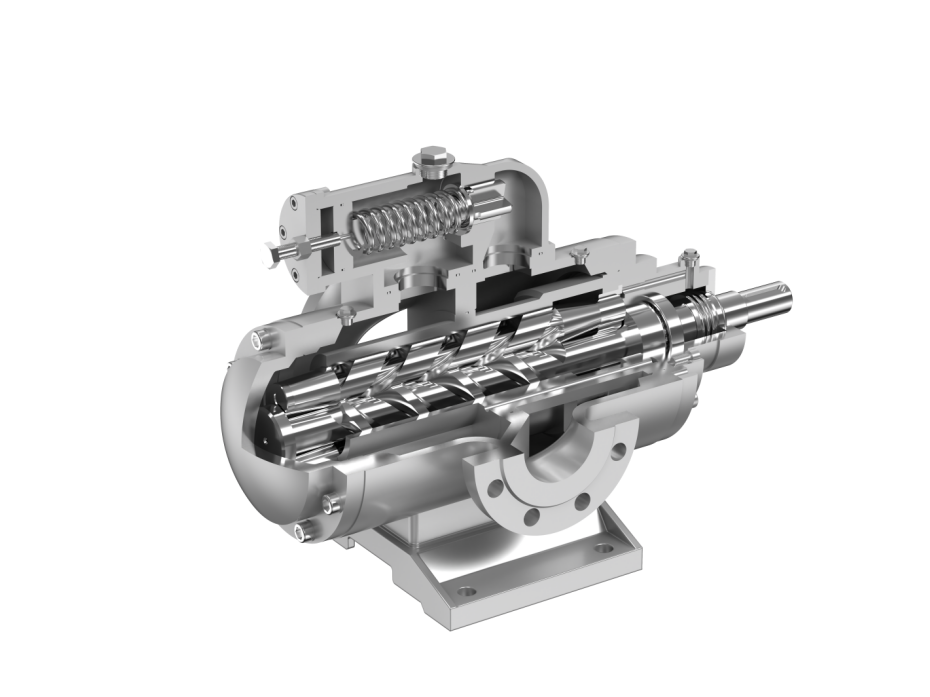

Unique Helical Profile for Smooth Conveyance

The triple – screw pump is composed of a helical profile with a special shape. When the screws rotate, the moving sealed chambers act like an orderly – operating “conveyor belt”, smoothly sucking in the liquid from the inlet and continuously and pulsation – free conveying it along the axial direction to the outlet. This unique working method ensures smooth operation of the pump, effectively reducing the vibration and impact generated during liquid flow, thus significantly reducing noise and ensuring a stable flow rate at all times. It provides a reliable guarantee for industrial scenarios with high requirements for flow – rate stability.

Axial Balance Design to Ensure Screw Stability

The main and driven screws adopt an axial balance design and are driven to rotate by hydraulic pressure. During operation, the various forces acting on the screws are balanced, keeping them in a stable equilibrium state. This design greatly reduces the risk of screw deformation due to uneven stress, ensuring that the screws can maintain good performance and accuracy under long – term high – intensity work, laying a solid foundation for the stable operation of the pump.

Non – Contact Screws to Prolong Equipment Life

The driving and driven screws don’t touch during operation. This feature basically prevents the wear resulting from direct friction between the screws. With minimal screw wear, it not only notably extends the service life of the screws themselves but also cuts down on equipment failures and maintenance costs caused by screw wear. It further boosts the overall service life and reliability of the pump. Additionally, the pump has a strong self – priming capacity. It can rapidly draw in the liquid when starting, eliminating the need for extra priming operations and greatly improving work efficiency.

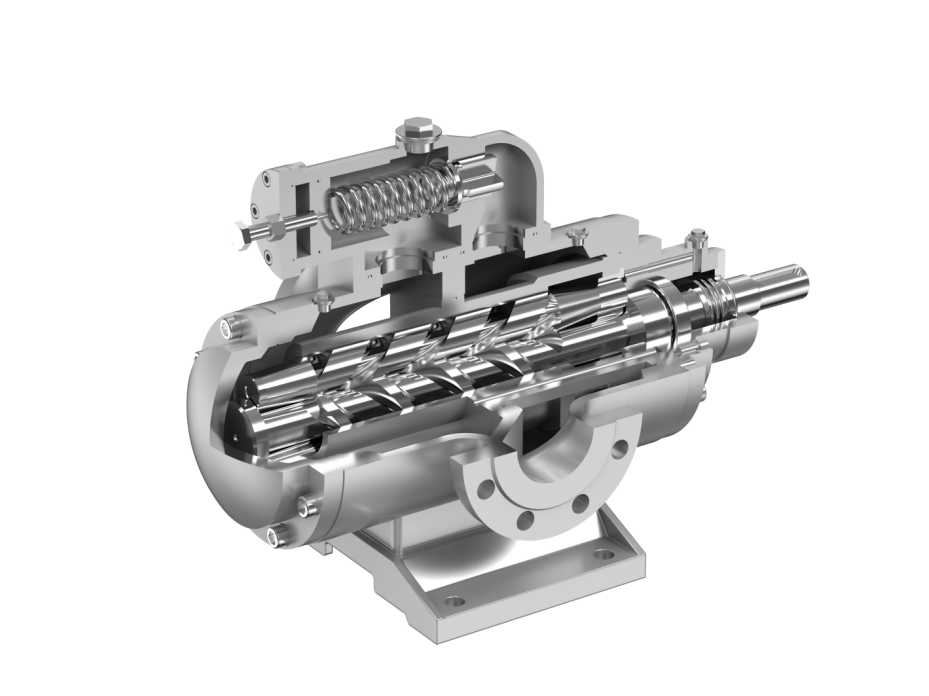

Submerged Structure to Optimize Layout and Performance

The pump’s suction port lies inside the oil tank, and the discharge is above the tank. The pump body connects fixedly to the oil tank, forming a submerged structure. On one hand, this structural design allows the pump to directly suck the liquid from the oil tank. It shortens the length and simplifies the complexity of the suction pipeline, reducing the cavitation risk. On the other hand, the integrated design of the pump body and the oil tank optimizes the equipment’s overall layout. It makes the equipment structure more compact, occupies less space, eases installation and maintenance, and also helps enhance the system’s integrity and stability.