In Russia’s key oil and gas sites—Siberian oil fields and Arctic LNG projects—three extremes long limit efficiency and equipment life: high gas content (over 80%), high sand levels, and -40℃ cold. Traditional pumps often fail here. But twin screw pumps, with their tailored design, stand out as the best fit for these tough conditions.

I. Why Traditional Pumps Struggle in Extreme Conditions

Siberian and Arctic environments demand tough pumps. Traditional systems fall short in key ways:

- High gas causes headaches: Single-screw pumps lock up when gas hits 30% or more. This leads to sudden flow drops and frequent shutdowns—they need repairs every 1-1.5 years. Centrifugal pumps need wellhead separators to work. This adds 30% to startup costs. Worse, burning off separated gas wastes energy and harms the environment.

- Sand wears pumps down: In Siberian flooded wells, crude carries lots of sand. Traditional pumps’ metal parts erode fast. A Tatarstan oil field once stopped production to fix this. Ordinary pumps lasted less than 6 months, costing over $1 million in losses.

- Extreme cold breaks equipment: Arctic LNG projects (like Yamal LNG) see -60℃ temperatures. Traditional pump seals crack. Metal parts snap from cold brittleness. This leads to constant breakdowns.

II. Twin Screw Pumps: 4 Key Fixes for Extreme Conditions

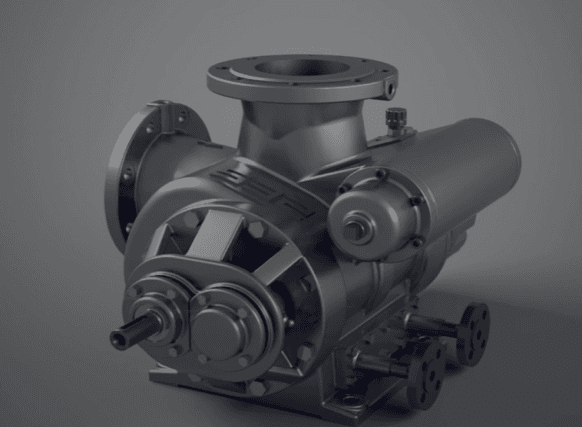

Twin screw pumps use smart design and strong materials to beat these challenges:

1. Handles mixed phases (gas, liquid, solids) easily

Twin screw pumps have a double-suction, symmetric design. Two interlocking screws form sealed chambers. They move gas, liquid, and solids all at once. Even with 100% gas, flow and pressure stay steady. No separators needed—saves on extra equipment costs.

2. Resists sand and wear

Twin screw pumps use tough parts. Screws are coated in tungsten carbide. Bushings are stainless steel. Surface hardness hits HRC60+. This stands up to long-term sand erosion. (Synchronous gears) keep screws from touching. This stops sand from jamming and causing extra wear.

In one Siberian field, twin screw pumps moved sandy crude (50,000 mPas viscosity) for 18 months without repairs. They lasted twice as long as single-screw pumps. Maintenance costs fell by 60%.

3. Works in -40℃ cold

For Arctic cold, twin screw pumps have heating jackets and cold-resistant lubrication. Hot oil flows through pump layers to keep them warm. Bearing boxes use special grease. This ensures easy startup at -40℃. Parts are made of cold-tough steel (like 316L stainless). This stops brittle cracking in the cold.

III. Twin Screw Pumps: A Must for Extreme Oil and Gas Work

In Siberian fields and Arctic LNG projects, twin screw pumps set new standards. They handle mixed phases without losing efficiency. They resist sand in harsh conditions. They stay steady in extreme cold. For oil and gas companies, choosing twin screw pumps cuts startup and maintenance costs. It keeps operations running—even in the harshest places.