Twin screw pumps are positive displacement rotary pumps, with core advantages of wide media adaptability, stable pulse-free delivery, and strong resistance to pressure and viscosity. They are especially suitable for complex working conditions and special environments where traditional centrifugal pumps (e.g., vane pumps) struggle. Their applicable scenarios can be precisely divided into three dimensions: media characteristics, operating parameters, and service environments, as detailed below:

1. Applicable Scenarios Based on “Media Characteristics”

The meshing structure of twin screws (forming closed chambers) gives them “tolerance” for media, making them ideal for the following types:

1.1 High-Viscosity/Thick Media

- Typical scenarios: Crude oil transportation, asphalt/residue transfer, lubricating oil filling, syrup/chocolate paste (food industry), creams/emulsions (cosmetics industry).

- Reason for suitability: Positive displacement principle does not rely on media kinetic energy. It stably delivers media with viscosity ranging from 1 to 100,000 cSt (even higher), with minimal flow fluctuation when viscosity changes (centrifugal pumps see sharp flow drops at high viscosity).

- Example: Crude oil transportation at oil wellheads (twin screws adapt to high viscosity during cold starts).

1.2 Multiphase Media (Gas/Solid-Containing)

- Typical scenarios: Multiphase flow at oil wellheads (oil-gas-water mixture), chemical reaction fluids (with bubbles), wastewater treatment (with small fibers/particles), mineral slurry transportation (with fine solids).

- Reason for suitability: Screw meshing gaps can hold small amounts of gas (avoids “air binding,” a common failure in centrifugal pumps). Rotors have no rigid friction with the pump chamber, tolerating media with solid content ≤5% and particle diameter ≤1mm (wear-resistant materials like hardened steel are optional).

1.3 Shear-Sensitive/Low-Damage-Required Media

- Typical scenarios: Yogurt/jam (food industry, avoids damaging pulp/probiotics), pharmaceutical liquids (pharmaceutical industry, prevents active ingredient inactivation), cosmetic serums (avoids emulsion breakdown).

- Reason for suitability: Rotors run smoothly, with no high-speed rotating vanes (centrifugal vanes cause high shear force). They minimize “mechanical damage” to media.

1.4 Corrosive/Hazardous/Toxic Media

- Typical scenarios: Acid-base solutions/organic solvents (chemical industry), sulfur-containing crude oil (petrochemical industry), toxic wastewater treatment (environmental protection).

- Reason for suitability: Corrosion-resistant materials (e.g., 316L stainless steel, Hastelloy) and leak-proof seals (mechanical/magnetic seals) prevent leaks, meeting explosion-proof standards (e.g., GB 50493).

2. Applicable Scenarios Based on “Operating Parameters”

Twin screw pumps excel when conditions demand “high pressure, low flow, or variable working conditions”:

2.1 High-Pressure Delivery Needs

- Typical scenarios: Long-distance pipeline transportation (crude oil pipelines), high-pressure reactor feeding (chemical industry), hydraulic system oil supply.

- Reason for suitability: Single-stage twin screw pumps reach discharge pressures of 1.6–4.0 MPa; multi-stage units exceed 10 MPa, with stable pressure (centrifugal pumps have pressure fluctuations).

2.2 Low Flow + High-Precision Delivery

- Typical scenarios: Precision metering (chemical additive injection), micro-lubrication systems (machine tools).

- Reason for suitability: Flow is proportional to rotational speed. With variable-frequency motors, it achieves flow accuracy within ±1%, better than centrifugal pumps.

2.3 Adaptability to Variable Viscosity/Working Conditions

- Typical scenarios: Alternating hot-cold media delivery, batch reactor feeding (frequent starts/stops).

- Reason for suitability: Flow is less affected by viscosity. It runs stably during starts/stops, avoiding “high starting current” in centrifugal pumps.

2.4 Short-Term Dry Running Needs

- Typical scenarios: Intermittent media interruptions (tank emptying), pump cavity degassing.

- Reason for suitability: Some models (with self-lubricating rotors) tolerate short dry running (≤5 minutes), while centrifugal pumps burn seals instantly when dry.

3. Applicable Scenarios Based on “Service Environments”

The structural strength and protection design of twin screw pumps allow them to adapt to harsh or special environments:

3.1 Harsh Industrial Environments (Dust/Vibration/Impact)

- Typical scenarios: Mineral slurry transportation (mining), molten metal additive delivery (metallurgy), oil wellhead operations (oil fields).

- Reason for suitability: Pump bodies use cast iron/steel for impact resistance. Seals have dust-proof designs, with protection ratings up to IP54/IP65.

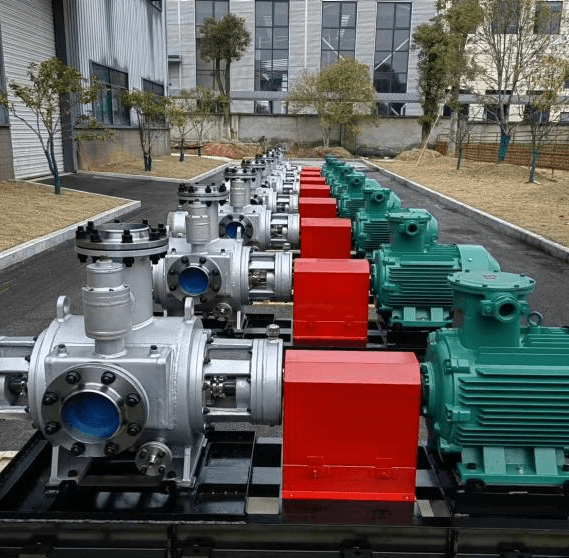

3.2 Outdoor/Field Unattended Environments

- Typical scenarios: Remote oil field stations, offshore platforms (offshore oil extraction).

- Reason for suitability: Integratable with remote monitoring modules (pressure/temperature sensors) and skid-mounted designs (e.g., Junyu Technology’s unattended skids), adapting to -40℃–60℃ temperatures.

3.3 Explosion-Proof/Hazardous Environments

- Typical scenarios: Chemical parks (flammable media), oil fields (methane leakage risks), coal mines (underground gas prevention).

- Reason for suitability: Equippable with explosion-proof motors (meeting ATEX Zone 1/2, IECEx Ex d IIB T4), avoiding sparks that cause explosions.

3.4 Clean/Hygienic Environments

- Typical scenarios: Dairy processing (food industry), pharmaceutical liquid delivery (pharmaceutical industry), cell culture (biology labs).

- Reason for suitability: Uses hygienic materials (316L stainless steel, Ra ≤0.8μm) and food-grade seals, meeting 3A standards and GMP requirements, supporting CIP/SIP cleaning.

4. “Non-Applicable Scenarios” to Note

Twin screw pumps are not universal. Prioritize other pump types for:

- Low viscosity (<1 cSt) + high flow (>1000 m³/h) + low pressure (<0.5 MPa): Centrifugal pumps (e.g., ISW type) are more cost-effective.

- Media with large particles (>5mm, e.g., coarse slag): Slurry pumps (centrifugal slurry pumps) prevent rotor jamming.

- Ultra-high pressure (>20 MPa) + minimal flow: Plunger pumps (metering plunger pumps) offer better precision.