Offshore oil and gas extraction brings four core challenges for pumping equipment. These are complex media, space limits, difficult maintenance, and reliance on imports.

Vigorous has 17 years of technical experience in screw pumps. It has developed a targeted twin-screw multiphase pump skid. This skid meets offshore platform needs in many ways. It fits working conditions, eases installation and maintenance, and cuts costs safely. It has become a key choice for localized replacement.

1. Stable Three-Phase Conveyance: Beating Complex Media Issues

Offshore produced fluids mix oil, gas, water, and sediment. This is a big challenge.

Traditional imported centrifugal pumps often fail. They “air bind” and shut down when gas content tops 5%.

Ordinary screw pumps can’t handle solid particles well. They need extra separators and compressors for pretreatment. This makes processes slow and costly.

Vigorous solves this pain point with two key designs. It uses special-profile screws and a double-suction rotor layout.

- It handles slug flow with 0-100% gas content nonstop. Even full gas conditions won’t stop it.

- It tolerates sediment with particle size ≤1mm and solid content ≤5%. Conveyance is pulse-free and won’t damage particles.

- No extra pretreatment equipment is needed. One skid simplifies extraction. It even gets some old, closed oil wells (shut for complex media) running again.

2. Modular Integration + Lightweight: Fitting Platform Limits

Offshore platforms have three strict constraints.

First, space is tight—equipment must be laid out compactly. Second, hoisting costs are high—heavy gear is hard to move. Third, the environment is harsh. High salt spray and strong vibration wear equipment fast.

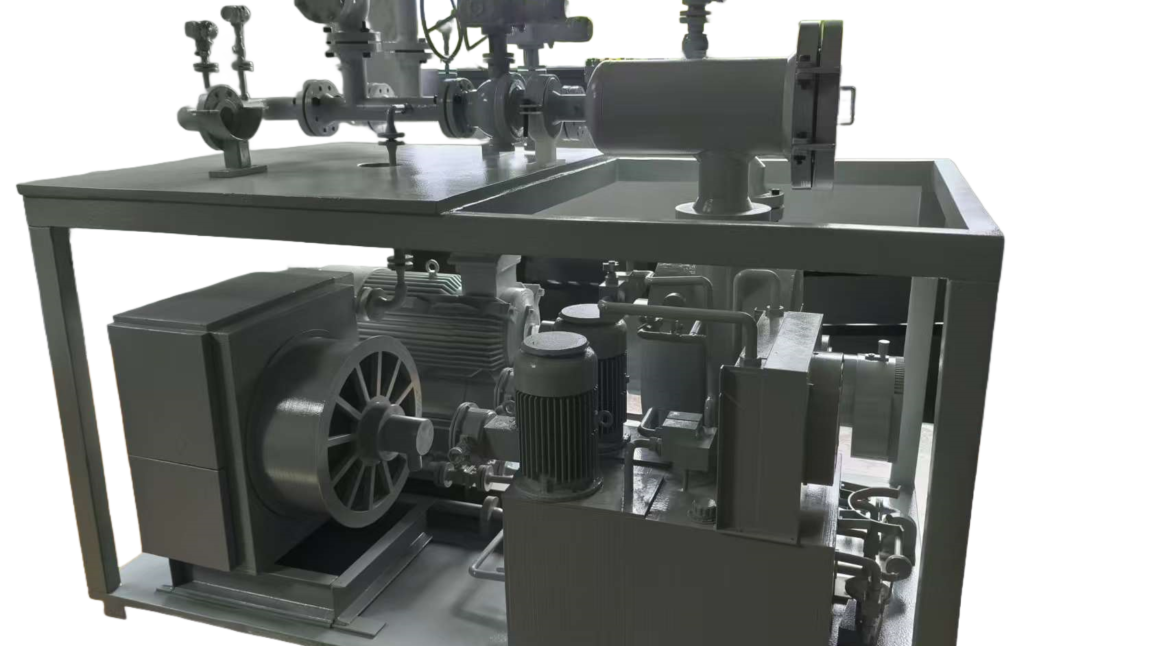

Vigorous’ “fully integrated skid design” meets these constraints perfectly.

- It combines core modules into one unit. These include the twin-screw multiphase pump, centralized lubrication system, and mechanical seal flushing system.

- On-site use only needs pipeline connections. Compared to traditional split equipment, installation and commissioning take 40% less time. Core parts don’t need disassembly during transport.

- The whole skid is treated for salt spray and vibration resistance. It works long-term in harsh offshore conditions. This cuts environment-caused failures.

3. Intelligent Maintenance: Cutting Offshore Operation Trouble and Costs

Offshore platforms are far from land. Maintenance here has big problems.

It’s hard to send staff to the platform. Fault responses are slow.

When imported equipment breaks, spare parts and technicians take 1-2 months to arrive. Shutdowns cause huge losses.

Vigorous added intelligent maintenance functions to the skid. This reduces reliance on on-site staff.

- Pressure, temperature, and vibration sensors collect data in real time. IoT modules enable remote visual monitoring. Onshore maintenance centers can check equipment status anytime.

- If medium viscosity or gas content changes, the system adjusts screw speed automatically. Flow stays stable—no need for staff to go to the platform.

- The screw rotor and shaft use a split structure. Maintenance doesn’t require taking the whole machine apart. Spare part replacement is easier.

4. Full-Chain Localization: Breaking Monopoly for Safety and Cost Gains

For years, European and American brands monopolized offshore platform pumping equipment.

A single unit is expensive to buy. Core spare parts take 6-12 months to deliver.

Supply chain fluctuations can “strangle” operations and slow extraction.

Vigorous has full-chain localization skills. It covers corrosion-resistant materials, precision screw processing, and intelligent control systems. This brings two big breakthroughs.

- One skid costs 30%-40% less than imported equipment. This cuts initial project investment sharply.

- Spare parts are delivered in 7-15 days. Emergencies get fast responses.

- The equipment passed strict tests. It works in high-pressure, high-corrosion environments below 1,500 meters in the South China Sea.

- It breaks total reliance on imported equipment. This secures the supply chain for offshore extraction gear.

Meta Description