1. First, Understand: What Exactly Is “Gas-Liquid-Solid Three-Phase Transportation” 1. First, Understand: What Is “Gas-Liquid-Solid Three-Phase Transportation” in Oil & Gas Extraction?

In the oil and gas industry, twin-screw pumps are used in over 40% of cases. They’re popular for a key reason.

The produced fluid isn’t a single medium (like pure oil or water). It’s a “three-phase fluid”—a mix of crude oil, natural gas, and sediment. Its traits come directly from the extraction scenario:

- Where does natural gas come from? In reservoirs, natural gas dissolves in crude oil. When extracting, wellhead pressure drops. Gas “escapes” and forms an unstable state—either “oil wrapping gas” or “gas wrapping oil.”

- Where do solid particles come from? Drill cuttings and reservoir sand enter the pipeline with produced fluid. This is worse in onshore old wells and offshore loose reservoirs—sand content keeps rising.

- What’s the trickiest problem? The three substances’ ratios change nonstop. For example, gas content might jump from 10% to 80%. This demands far more adaptability from equipment than single-medium transport.

2. Traditional Equipment’s “Three-Phase Dilemma”: Why Do They “Quit” When Gas Content Tops 5%?

Facing three-phase transport, traditional equipment isn’t “incapable.” It’s “outdated in principle.” That’s why many oilfields need extra pretreatment gear:

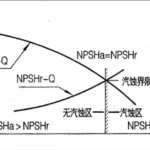

1. Centrifugal Pumps: Gas Content Is a “Fatal Flaw”

Centrifugal pumps work simply. They use high-speed rotating impellers to create centrifugal force. This “flings” medium to the outlet.

But once gas content exceeds 5%, trouble hits. Gas often forms an “air cavity” at the impeller’s center. This is called the “air binding effect”:

- The “air cavity” blocks liquid from touching the impeller. The pump can’t discharge fluid—sometimes it shuts down entirely.

- To fix this, oilfields usually add a “three-phase separator.” They separate gas first, then use centrifugal pumps to move oil. This adds a step—and extra equipment costs.

2. Ordinary Screw Pumps: Can’t Stand Sand Wear

Ordinary single-screw pumps (or low-precision twin-screw pumps) move medium via sealed cavities. These cavities form when rotors and stators mesh.

But this design has a clear weakness:

- Rotors and stators touch directly. If the medium has sand over 0.5mm, wear speeds up. Spare parts need replacing every 3–6 months on average.

- So traditional setups add a “cyclone desander.” It filters solid particles first. This makes the system more complex.

3. High-Pressure Conditions: An Extra “Burden”

Deep oil and gas wells (especially offshore ones) have wellhead pressure of 25–35MPa.

Traditional equipment struggles here: either it can’t handle the pressure (ordinary screw pumps usually max out at 15MPa), or it needs a “pressure reducing valve.”

- A pressure reducing valve wastes about 30% of energy. It also makes three-phase fluid more unstable due to pressure swings.

3. Twin-Screw Pumps’ “Solution Principle”: Why They Handle 0–100% Gas Content Steadily?

Twin-screw pumps are the “main force” for three-phase transport. Their secret is the “rotor meshing + non-contact sealing” design. It fixes traditional equipment’s pain points at the root:

1. Double-Suction Rotors: Balance Pressure, Ignore Gas Swings

A twin-screw pump’s core is two synchronously rotating screws. Most use a “double-suction” design—medium is sucked in from both ends of the screws.

- Advantage 1: Automatic pressure balance. No matter how gas content changes, pressure stays equal at both ends of the screws. Gas buildup won’t cause uneven force or more vibration.

- Advantage 2: Continuous sealed cavities. The two screws have “conjugate profiles” (common ones are 8-shaped or involute). When they mesh, they form a series of small, independent sealed cavities.

These cavities “push” medium from inlet to outlet. Even if a cavity is full of gas, it still moves steadily. No “air binding” happens.

This is why twin-screw pumps handle 0–100% gas content: gas is no longer a “problem”—it moves with the liquid.

2. Non-Contact Design + Wear-Resistant Materials: No Fear of Sand

Unlike ordinary screw pumps (where rotors stick to stators), twin-screw pumps have tiny gaps. These gaps are 0.1–0.3mm—between screws and the pump body, and between the two screws.

- What the gaps do: Sand particles flow with the medium in the gaps. They don’t get squeezed or wear down the screws.

- Material upgrades: Screws and pump bodies use 316L stainless steel. Some get tungsten carbide coatings (hardness over HV800). Even with 5% solid content, they run steadily long-term.

3. High-Pressure Resistant Structure: Connect Directly to Wellheads, No Pressure Reduction

To meet deep-well pressure needs, twin-screw pump bodies use “integral forging.” They also have bellows mechanical seals.

- Pressure resistance tops 35MPa. They connect directly to high-pressure wellheads—no pressure reducing valve needed.

- This saves energy. It also cuts down on pressure swings that disrupt three-phase fluid.

4. Practical Tips: 3 Key Parameters for Choosing Twin-Screw Pumps

Once you understand the principle, don’t get confused by complex specs. Focus on these 3 core indicators:

- Gas content range: Pick models marked “0–100% full gas content compatible.” Pay extra attention to “slug flow capability.” Slug flow is common offshore—gas content can spike suddenly.

- Solid content and particle size: Check the “max solid content” (usually ≤5%) and “max particle size” (recommended ≤1mm). If your oilfield has high sand content, ask for a custom “anti-clog inlet.”

- Pressure resistance level: Choose based on wellhead pressure. 16–25MPa works for onshore old wells. For offshore deep wells, pick 35MPa or higher. This avoids damage from insufficient pressure resistance.

5. Summary: Three-Phase Transport’s “Technical Logic”—From “Multi-Equipment Prep” to “Single-Pump Direct Transport”

The core challenge of oil and gas three-phase transport is a contradiction: “unstable fluid” vs. “mismatched equipment principles.”

Traditional solutions add equipment (separators, desanders) to reduce fluid complexity. Twin-screw pumps take a different approach: they boost adaptability via structural innovation. This cuts out the pretreatment step entirely.

For oil and gas professionals, understanding equipment principles helps you pick the right gear for your wells. Twin-screw pumps are used more and more not because they “replace” old equipment. They’re a “dedicated solution”—built specifically for three-phase transport.

If you have questions about selection, talk further. Share your well’s gas content, sand content, wellhead pressure, and other conditions. We can find the right fit.