I. Opening: The Selection Dilemma in Gas Conveyance—Why Compressors Aren’t the Only Choice Anymore?

Medium-to-high pressure gas conveyance is key in oil & gas extraction (like shale gas wells or offshore slug flow) and chemical tail gas recovery. For years, it relied on compressors. But real-world use brings three big pain points:

- Short pure gas runtime: Compressors work via “positive displacement + forced cooling.” When moving pure gas nonstop, their exhaust temp hits over 120°C. They need shutdowns every 2–3 hours to cool—stopping conveyance.

- Bulky systems: To handle gas-liquid mixes, compressors need extra gear: three-phase separators, buffer tanks, and coolers. This complex setup takes more space and costs more to buy.

- Costly maintenance: Compressors need frequent filter changes and cooling system fixes. Annual maintenance costs often top RMB 150,000. Worse, shutdowns cause big losses—like 5–8 tons of crude oil lost daily per well.

Our twin-screw multiphase pump has a 1:30 compression ratio and can move pure gas nonstop for long periods. It’s more cost-efficient for these complex conditions. Below is a comparison across 6 core areas.

II. Core Comparison: Twin-Screw Pump vs. Compressor (Data Included)

1. Core Capabilities (Fixing “Continuous Conveyance” Pain Points)

| Comparison Item | Traditional Compressors (Reciprocating/Screw) | Our Twin-Screw Pump | Key Differences |

|---|---|---|---|

| Continuous Pure Gas Runtime | ≤2 hours (shuts down from overheating) | ≥72 hours (no issues) | Compressors need compression chamber cooling—pure gas lacks liquid to cool them. Our pumps use “sealed cavity conveyance + heat-resistant coatings (e.g., tungsten carbide)” to avoid overheating. |

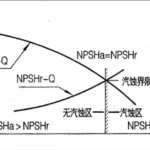

| Compression Ratio (Medium-High Pressure) | Theoretical 1:50, but drops to 1:20 for gas-liquid mixes | Stable 1:30 (works for pure gas or mixes) | Compressors cut load to stop liquid from damaging their chambers. Our pumps use “multi-stage sealed cavities”—they handle gas, liquid, and solids with no ratio drops. |

| Gas-Liquid-Solid Conveyance | Needs pre-separation (remove liquid/solids) to move pure gas | Moves media with 0–100% gas and ≤5% solids directly | Compressors have no anti-clog parts—liquid/solids wear their valves. Our pumps have “non-contact rotors + anti-clog inlets”—no pre-treatment needed. |

2. Equipment Systems (Save Space & Simplify)

| Comparison Item | Traditional Compressor Systems | Our Twin-Screw Pump | Core Value |

|---|---|---|---|

| Required Gear | Compressor + separator + buffer tank + cooler | Single skid-mounted twin-screw pump | Cuts 3 core equipment units. Lowers leak risks from pipe connections between gear. Also reduces skid transport costs—like 30% less for offshore platforms. |

| Floor Space | ~20 m² (including aux gear & walkways) | ~3.5 m² (skid-mounted, no extra walkways) | Perfect for tight spaces: offshore platforms, downhole skids. Cuts space by 82.5%. |

| Installation Time | 15–20 days (align gear & debug pipes) | 48 hours (only connect pipes + set parameters) | Speeds up commissioning. Gets wells/plants online faster—like 18 days earlier for oil wells, adding over RMB 500,000 in revenue. |

3. Costs (Full Lifecycle—More Than Just Purchase Price)

| Cost Type | Traditional Compressors (5-Year Cycle) | Our Twin-Screw Pump (5-Year Cycle) | 5-Year Total Savings |

|---|---|---|---|

| Initial Purchase Cost | ~RMB 2,000,000 (with aux gear) | ~RMB 1,500,000 (skid-mounted) | RMB 500,000—no extra pre-treatment gear costs. |

| Annual Maintenance Cost | RMB 150,000 (filters, cooling, labor) | RMB 30,000 (only oil changes + remote checks) | RMB 120,000/year; RMB 600,000 total. Our pumps have no fragile parts (e.g., compressor valves)—fewer unexpected repairs. |

| Annual Energy Cost | ~80,000 kWh (cooling + full-load running) | ~50,000 kWh (variable speed, no extra cooling) | At RMB 0.6/kWh: RMB 18,000/year; RMB 90,000 total. |

| Shutdown Losses | ~RMB 800,000/year (3 daily shutdowns; 0.7 tons oil lost each) | RMB 0 (nonstop running) | RMB 4,000,000 total—the biggest saving. |

| Total 5-Year Cost | ~RMB 7,090,000 | ~RMB 1,640,000 | RMB 5,450,000 saved—our pump costs just 23% of compressors. |

III. Why Twin-Screw Pumps Are Cheaper & More Stable: The Tech Behind It

- Different compression methods:Compressors use “intermittent positive displacement.” They squeeze gas repeatedly with pistons or rotors. This makes lots of heat—needing extra cooling.Twin-screw pumps use “continuous sealed cavity conveyance.” Two meshing screws form airtight cavities. They push gas from low to high pressure—no backflow, no extra heat. Great for nonstop use.

- Different media compatibility:Compressors have fragile “chambers + valves.” Liquid or solids jam or wear them out.Twin-screw pumps have “non-contact rotors + wide channels.” They handle small solids. Gas and liquid can mix in their cavities—no pre-separation needed.

- Different control logic:Compressors run at full load. They can’t adjust for changing gas content.Twin-screw pumps use variable-frequency control. They speed up to keep pressure when gas content is high. They slow down to save energy when it’s low. It’s “on-demand output.”

IV. When to Choose Twin-Screw Pumps?

- Complex conditions: Need to move gas-liquid-solid mixes (e.g., well fluid, chemical slaggy tail gas) or handle big gas content swings (0–100%).

- Tight spaces: Offshore platforms, downhole skids, or small chemical plants—no room for compressors + aux gear.

- Cost-sensitive projects: Care about full-lifecycle costs (especially shutdown losses and maintenance). Want “low investment + high stability.”

- Unmanned sites: Remote oil fields or automated factories. Need gear that runs nonstop with little manual check.

Conclusion: Upgrade Your Gas Conveyance—From Single-Function to Multi-Function

Compressors still work for pure high-pressure gas. But in oil & gas or chemical settings—where media is complex and conditions change—our twin-screw pump shines. It has a 1:30 compression ratio and long pure gas runtime. It gives four big benefits: fewer gear, less space, lower costs, and no shutdowns.

Choosing isn’t “pump vs. compressor.” It’s “does it fit your conditions?” If you struggle with gas-liquid mixes, frequent shutdowns, or high maintenance—our twin-screw multiphase pump is the better choice.