1. Introduction: The Hidden Cause of 70% Pump Failures

When a chemical pump leaks suddenly or an oilfield pump shuts down unexpectedly, check maintenance records. You’ll find 70% of failures come from mechanical seal malfunctions.

Each such failure costs over RMB 8,000 on average. This includes fees for cleaning up medium leaks, equipment repair costs, and order delays from production line downtime.

Mechanical seals aren’t just simple “gaskets.” They’re precision systems balancing accuracy, materials, and working conditions. For oil, gas, and chemical industries following API 682 standards, they’re the “first line of defense” for pump compliance and reliability.

This article uses domestic cases and industry data to explain mechanical seals. It helps you avoid common mistakes.

2. Why Mechanical Seals Are a Pump’s “Lifeline”

Mechanical seals differ from traditional packing seals. They use a “dynamic seal face + elastic compensation” design. This fixes three key pain points in domestic industrial settings:

2.1 Ultra-Low Leakage: Stay Compliant

API 682 has clear requirements. All seal leakage rates must be below 1000 mL/m³ (about 0.1 drops per minute). Double seals can even achieve “zero leakage.”

This is critical for pumps handling toxic or flammable media. A Jiangsu chemical plant was fined RMB 200,000 by environmental authorities. The issue? Packing seals leaked too much. After switching to API 682-compliant mechanical seals, compliance risks disappeared.

2.2 Longer Life: Cut Maintenance Costs

Qualified mechanical seals last at least 25,000 hours (about 3 years). That’s over 5 times longer than packing seals.

Take a twin-screw pump at a North China oilfield. Before, it used packing seals. It needed 2 shutdowns yearly for replacements. Each cost RMB 5,000 (including labor and parts). After switching to mechanical seals, replacements are only needed once every 3 years. Annual maintenance costs dropped by 80%.

2.3 Protect the Shaft: Extend Pump Life

Mechanical seals have a sleeve. It keeps the medium from touching the pump shaft directly. This stops corrosive fluids or particles from wearing the shaft.

Data from a Guangdong wastewater plant shows: Pumps with mechanical seals had longer shaft life. It went from 1 year to 5 years. Total lifecycle cost per pump (including shaft replacement) fell by RMB 60,000.

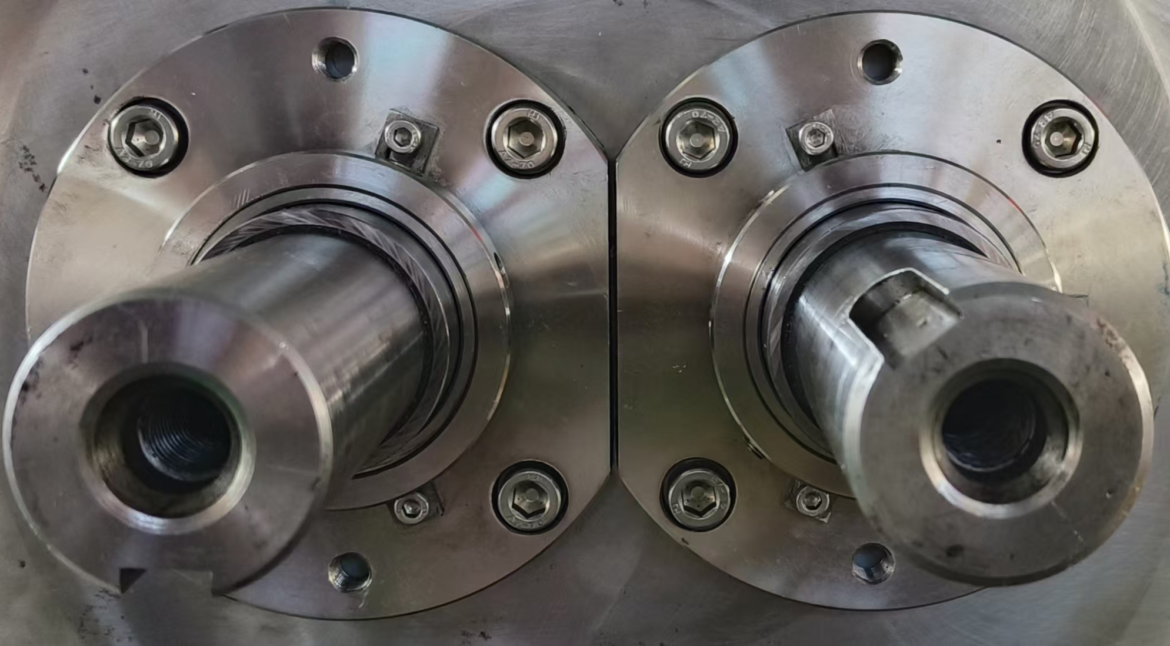

3. How Mechanical Seals Work & Their Core Types

3.1 Simple Working Logic: The “Two Faces” Balance

The core of a mechanical seal is the tight fit between the rotating ring and stationary ring. The process has 3 steps:

- The rotating ring spins with the pump shaft. The stationary ring is fixed to the pump casing.

- Springs (or bellows) provide steady pressure. This keeps the two seal faces tightly fitted (flatness error ≤ 0.005 mm).

- A 5–10 μm fluid film forms between the seal faces. It stops leaks and lubricates the faces to avoid dry friction.

If the fluid film breaks, dry friction damages the seal faces in seconds. This causes 90% of sudden leaks.

3.2 3 Core Types for Different Scenarios (API 682 Classification)

| Type | Structural Features | Temperature Range | Ideal Applications |

|---|---|---|---|

| Type A Seal | Multi-spring, push-type, cartridge design | -40°C ~ 176°C | Conventional oil/water transfer (e.g., power plant circulating pumps) |

| Type B Seal | Bellows structure, better compensation | -40°C ~ 176°C | Medium-viscosity media (e.g., crude oil/diesel pumps) |

| Type C Seal | Metal bellows, no rubber parts | -40°C ~ 400°C | High-temperature media (e.g., refinery thermal oil pumps) |

3.3 Single vs. Double Seals: Choose by Risk Level

- Arrangement 1 (Single Seal): Simple structure, low cost. Good for non-hazardous media (water, lubricating oil). But higher leakage risk.

- Arrangement 3 (Double Seal): Uses external barrier fluid (pressurized above the seal chamber). Achieves zero leakage. Suitable for toxic/flammable media (e.g., coal chemical gas pumps).

A Shanxi coal chemical enterprise replaced single seals with double seals. Toxic gas leaks stopped completely. It passed safety inspections by emergency management authorities.

4. 3-Step API 682-Compliant Selection: Avoid 80% of Failures

Wrong selection is the main reason mechanical seals fail early. Follow these steps to match domestic working conditions:

4.1 Step 1: Understand the Medium’s “Traits”

Medium properties decide material choices. Here are references for common domestic scenarios:

- Corrosiveness: For acids (pH < 2, e.g., electroplating wastewater), use SiC (silicon carbide) seal faces + Hastelloy parts. For neutral media (e.g., cooling water), 316 stainless steel + alumina works.

- Solid Content: For media with particles > 50 mg/L (e.g., mine sludge, sand-containing crude oil), use “hard-on-hard” seal faces (SiC vs. SiC). Add a Plan 32 external flushing system to filter particles.

- Viscosity: For high-viscosity media (> 500 cSt, e.g., asphalt, syrup), use large-diameter springs to prevent jamming. For low-viscosity media (< 50 cSt, e.g., LNG, liquid propane), add a Plan 53A forced lubrication system.

4.2 Step 2: Match Operating “Limits”

Working conditions vary across domestic industries. Focus on 3 key parameters:

- Temperature: In northern winter low temps (< -20°C, e.g., Northeast oilfields), use 316L bellows seals. This avoids brittle fracture. For high temps (> 180°C, e.g., chemical reactor feed pumps), choose Type C metal bellows seals. Pair with a Plan 21 cooling system.

- Pressure: For low-pressure conditions (≤ 0.6 MPa, e.g., tap water pumps), use unbalanced seals. For high-pressure conditions (> 10 MPa, e.g., high-pressure injection pumps), balanced seals (load factor < 1) are a must.

- Speed: For high-speed pumps (seal face speed > 23 m/s, e.g., centrifugal compressor pumps), use stationary springs. This prevents rotating springs from failing due to centrifugal force.

4.3 Step 3: Match Risk “Levels”

| Medium Risk Level | Recommended Seal Type | API 682 Leakage Limit | Domestic Applications |

|---|---|---|---|

| Non-Hazardous (Water) | Arrangement 1 (Single Seal) | ≤ 10 drops/min | Municipal water, power plant circulating water |

| Moderate Risk (Crude Oil) | Arrangement 2 (Double Seal) | ≤ 1 drop/min | Onshore oilfield transfer pumps |

| High Risk (Toxic/Flammable) | Arrangement 3 (Double Seal) | Near-zero leakage | Coal chemical, fine chemical toxic media pumps |

5. 5 Maintenance Tips to Double Seal Life

Domestic pump users often shorten seal life with bad maintenance. Data from a pump maker shows: Standard maintenance extends seal life from 1 year to over 3 years. Here are 5 key tips:

5.1 Prime the Pump Before Startup—No Dry Running

Five seconds of dry running equals 8 hours of normal wear. Correct operation: Open the pump’s vent valve. Fill the pump chamber with fluid before starting. For remote sites (e.g., oilfield wellhead pumps), install an electric vent valve for automatic priming.

5.2 Open Valves Slowly—Let the Fluid Film Form

After startup: Open the suction valve first. Then slowly open the discharge valve over 30 seconds. Sudden high flow breaks the seal face fluid film. An Xinjiang oilfield used this method. Seal failure rates dropped by 40%.

5.3 Choose the Right Flushing Plan

Here are common domestic flushing plans:

- For clean, high-temperature media (e.g., thermal oil, steam-heated crude oil), use Plan 11 self-flushing. Keep flow at 3–5 L/min.

- For particle-laden, easy-to-crystallize media (e.g., coal mine sludge, caustic soda), use Plan 32 external flushing. Use clean water to isolate impurities.

5.4 Monitor Temperature—More Sensitive Than Vibration

Install a PT100 thermocouple on the seal gland. Set an alarm for “medium temperature + 20°C.” Tests show: Every 10°C temperature rise increases seal wear by 1.8x. A 48-hour early warning prevents sudden leaks. For example, it stops seal overheating from blocked cooling pipes in chemical pumps.

5.5 Follow Shutdown Steps—Prevent Impact

Correct sequence: Close the discharge valve → stop the motor → close the suction valve. In winter (e.g., sub-zero northern China), purge with nitrogen for 5 minutes after shutdown. This stops media crystallization (e.g., brine, ethylene glycol) from scratching seal faces.

6. Troubleshooting Common Failures (With Domestic Cases)

| Symptom | Root Cause | Solution | Domestic Case Reference |

|---|---|---|---|

| Sudden Leakage | Seal face damage (particle ingress) | Check the flushing system. Add a 10 μm filter. | A Henan mine pump added a filter. Leaks were fixed completely. |

| Short Life (< 6 Months) | Coupling misalignment (> 0.1 mm) | Calibrate with a laser alignment tool. Keep deviation ≤ 0.02 mm. | A Zhejiang chemical firm calibrated couplings. Seal life went from 4 months to 2 years. |

| Seal Face Overheating | Insufficient flushing flow | Increase flow to 3 L/min. Check for blocked pipes. | A Shandong refinery cleared blocked pipes. Overheating was solved. |

7. Conclusion: The Basis of Compliance and Reliability

Mechanical seal failure is never “sudden.” It’s the result of “wrong selection + bad maintenance.” As domestic environmental and safety standards get stricter, choosing API 682-compliant seals and following standard maintenance is key. It not only avoids failure costs but also helps enterprises pass compliance inspections.

If you need custom seal solutions for specific scenarios (e.g., twin-screw pumps, wastewater pumps, chemical process pumps), share details like medium type, operating pressure, and temperature. We’ll tailor a plan for domestic working conditions.