I. In-Depth Analysis of Coal bed methane Exploitation Operation Conditions and Technical Bottlenecks

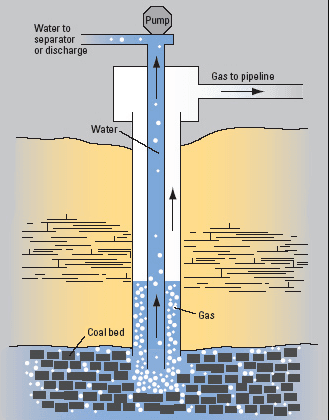

(1) Coupling Characteristics of Geomechanics and Gas Production Mechanism

- Adsorption-desorption kinetic parameters:

▶ High-rank coal reservoir adsorption constant a=30-45m³/t, b=2.0-3.5MPa (Qinshui Basin measurement data)

▶ Desorption hysteresis effect: When pressure reduction rate >0.1MPa/d, methane desorption volume decreases by 15-20% - Seepage physical field characteristics:

▶ Fracture system permeability variation index n=1.2-1.8 with effective stress (Ordos Basin data)

▶ Critical velocity of coal powder migration 0.3-0.5m/s, pore throat blockage rate increases by 40% beyond this value

(2) Quantitative Analysis of Multiphase Flow Conditions

| Exploitation Stage | Gas-liquid Ratio Range | Medium Characteristic Parameters | Traditional Equipment Failure Modes |

|---|---|---|---|

| Drainage-pressure reduction period | 1:10-1:5 | Water phase viscosity 1-5cSt, coal powder <50ppm | Centrifugal pump cavitation (NPSHr required >5m) |

| Gas production ascending period | 1:5-5:1 | Gas-liquid slip velocity difference 2.1m/s | Screw pump gas compression ratio insufficient <1.8:1 |

| Stable production-decline period | 5:1-10:1 | Methane concentration >95%, with condensate oil | Compressor surge (flow fluctuation ±15%) |

(3) Technical Gaps in Equipment Adaptability

- Hydrodynamic defects:

Centrifugal pump impeller shear rate >5000s⁻¹, causing gas fragmentation and cavitation nuclei - Safety design vulnerabilities:

Ordinary pumps only reach explosion-proof grade Ex d IIB T3, unsuitable for CBM wells with methane concentration >15%

II. Multidimensional Challenges and Data Support for Water-Flooded Well Recovery Operation Conditions

(1) Corrosion and Wear Mechanism of Water-Invasion Media

- Electrochemical corrosion parameters:

▶ When H₂S partial pressure >0.003MPa, stress corrosion cracking (SSC) latency <30 days

▶ When CO₂ partial pressure >0.02MPa, uniform corrosion rate >0.15mm/year (NACE TM0183 standard) - Solid particle erosion effect:

When sand content >100ppm and particle size >50μm, pump valve seat wear rate reaches 0.05mm/100h

(2) Laws of Multiphase Flow Rheology

- Water cut-viscosity correlation model:

When water cut increases from 50% to 80%,

▶ Newtonian water phase viscosity ↑1.2 times

▶ Emulsified liquid viscosity ↑8-12 times (surfactant content 100-200ppm) - Flow pattern transition critical conditions:

When water cut >75%, wellbore flow pattern transitions from annular mist flow to bubble flow, lifting efficiency drops by 35%

(3) Failure Modes of Exploitation Technology

- Characteristics of water channeling pathways:

High-permeability zone water flooding velocity 15-20m/d, 100-200 times that of matrix seepage - Technical bottlenecks of water shutoff:

When temperature >80℃ and salinity >10⁴mg/L, gel-type water shutoff agent gel strength decays by 50%

III. Technical Innovation System for HWMPS450 Dual-Operation Adaptation

(1) CBM Operation-Specific Technical Modules

1. Dynamic Desorption Coordination System

- Pressure reduction-gas production coupling control:

▶ Dual closed-loop control (pressure loop + flow loop), pressure reduction rate control accuracy ±0.05MPa/d

▶ Coal powder filtration system (3μm precision), blockage rate reduced by 70% compared to traditional solutions

2. Core Technology of Gas-Liquid Mixed Transportation

- Hydrodynamic optimization:

▶ Screw profile: Adopts 5:6 asymmetric tooth shape, gas compression ratio reaches 3.2:1 (traditional 2:1)

▶ Flow channel design: Flow area 1.8 times larger than centrifugal pumps, flow velocity controlled below 1.8m/s

3. Explosion-Proof Safety System

(2) Customized Solutions for Water-Flooded Well Operation Conditions

1. Anti-Corrosion and Wear-Resistant System

- Material engineering innovation:ComponentMaterial SolutionCorrosion Rate ComparisonPump Body2205 Duplex Steel (Cr22/Ni5/Mo3)0.05mm/year (traditional 0.2mm)ScrewTungsten Carbide Coating (500μm thickness)Wear amount <0.1mm/1000hSealing ElementsPEEK + Carbon Fiber ReinforcementService life extended to 12 months

2. Intelligent Lifting Adjustment Algorithm

- Multi-parameter fusion control:

▶ Input variables: Water cut, viscosity, wellbore depth

▶ Output control: Stroke (0.5-3m), pumping speed (2-12 strokes/min)

▶ Control accuracy: Lifting pressure fluctuation ≤±0.08MPa

3. Water Shutoff Coordination Technology

- Dynamic profile control integration:

▶ Built-in chemical injection pump (flow 0-50L/h)

▶ Uniformity of shutoff agent and fluid mixing >90%

IV. Industrial Application Cases and Quantitative Effects

(1) CBM Well Drainage Case (Ordos Basin)

- Operation parameters:

Coal seam permeability 0.6mD, initial formation pressure 3.5MPa, target desorption pressure 1.5MPa - System operation data:

▶ Drainage stage: 450m³/h continuous drainage, pressure reduced to 1.8MPa within 15 days

▶ Gas production stage: Gas-liquid ratio increased from 1:8 to 6:1, compressed pressure 0.8MPa

▶ Key indicators: Gas production efficiency increased by 42% compared to traditional solutions, equipment failure rate reduced by 85%

(2) Water-Flooded Well Recovery Case (Sichuan Oilfield)

- Conditions before treatment:

Water cut 92%, H₂S concentration 120ppm, tubing perforation cycle 3 months - HWMPS450 application effects:IndicatorBefore TreatmentAfter TreatmentImprovement RateDaily Production8t43t437.5%Corrosion Rate0.32mm/year0.07mm/year78.1%Maintenance Cycle3 months24 months700%

USGS. (May 28, 2015). Coal-Bed Methane: Potential and Concerns [Online]. Available: http://pubs.usgs.gov/fs/fs123-00/fs123-00.pdf