Description

Features

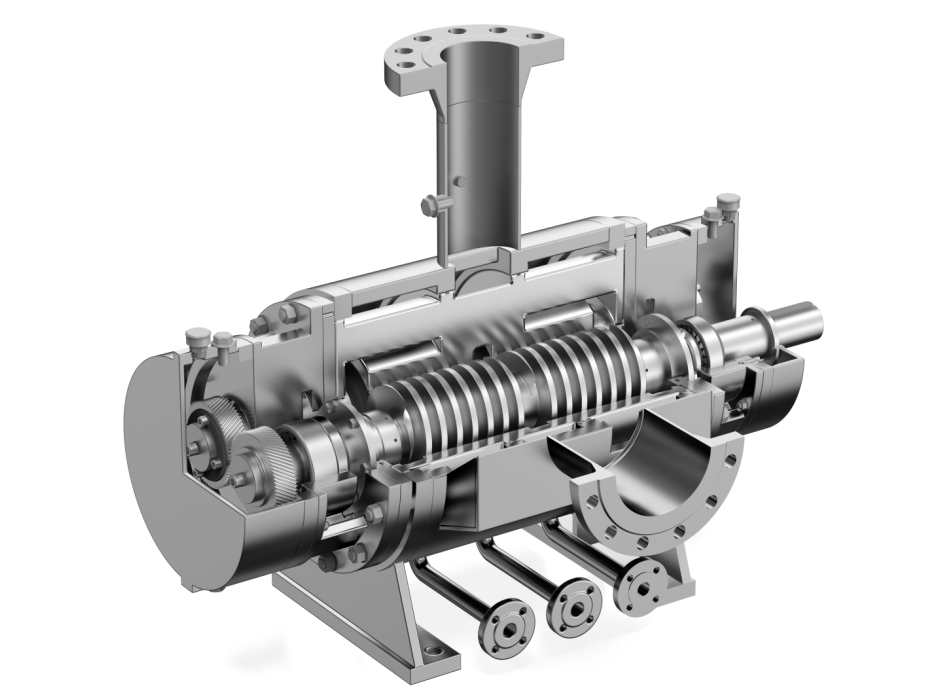

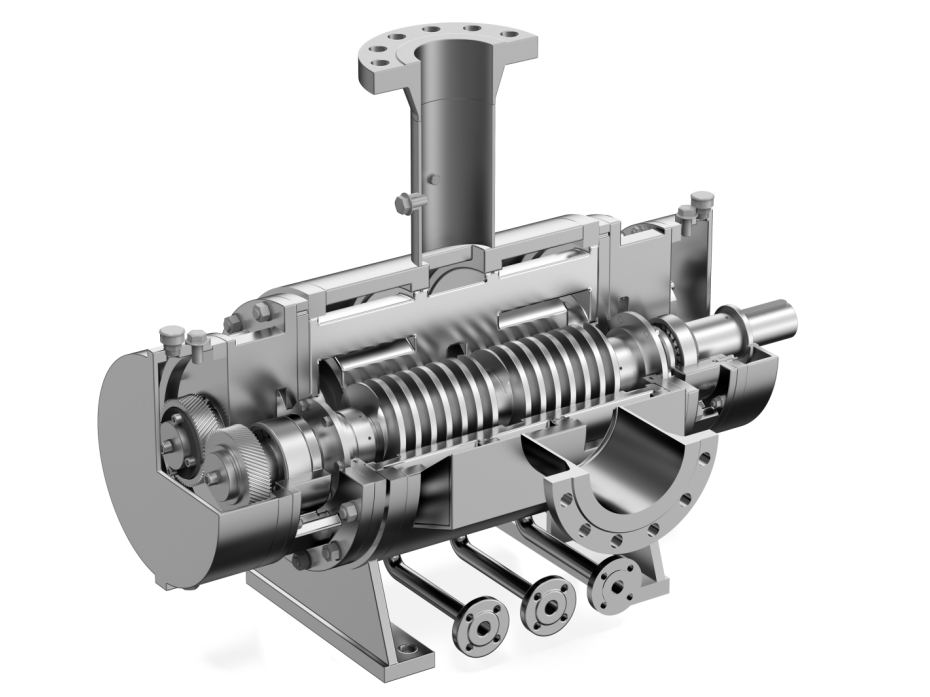

| 1.integral design, spindle and thread are machined out of one single piece, accuracy, rigidity | 5.Bearing supported on each end,eliminate contact between screw and casing, no metal scraping, long lifespan. |

| 2.Torque delivered by timing gears, stable driving, low noise | 6.axial balanced rotor, no axial force, low bearing load |

| 3.Welded pump body, replaceable sleeves, easier maintenance, low cost | 7.With back-flow pressure relief valve, safe and energy efficiency |

| 4.specialized rotor, minimal pulse and NPSHr

|

8.Built for high pressure application, high GVF |

Application Scenarios:

-

Petrochemical Industry

- Crude Oil Transportation: In oilfield exploitation, the crude oil collected from the wellhead needs to be transported to gathering stations or refineries. Twin – screw pumps have a strong self – priming ability and can adapt to high – viscosity substances. They can directly draw crude oil from the oil gathering pond near the wellhead and overcome the resistance of long – distance pipeline transportation to ensure a stable supply.

- Chemical Raw Material Transportation: Chemical production involves a variety of raw materials, such as polymer solutions, resins, and coatings, with large differences in viscosity. Twin – screw pumps can transport these raw materials smoothly. Their low – shear – force feature avoids damaging the chemical structure of the raw materials, thus ensuring production quality. For example, in synthetic rubber production, precise transportation of polymer solutions is crucial, and twin – screw pumps can meet this requirement.

- Refined Oil Transportation: Within refineries and in the processes of oil product storage and transportation, twin – screw pumps are used to transport refined oil products such as gasoline, diesel, and lubricating oil. Their characteristics of uniform flow rate and stable pressure ensure efficient and accurate transportation under different working conditions, meeting the supply requirements of various links for oil products.

-

Food and Beverage Industry

- Sauce and Syrup Transportation: When producing products such as ketchup, chocolate sauce, and syrup, the materials are highly viscous and may contain particles or fibers. Twin – screw pumps’ low – shear – force transportation can not only maintain the texture and taste of the sauce and syrup but also efficiently complete the transportation task from the mixing tank to the packaging equipment.

- Liquid Transportation of Juice, Milk, etc.: In beverage production, twin – screw pumps are used to transport easily – spoiled liquids such as juice and milk. Their hygienic design, low – shear – force, and stable flow control can prevent the liquid from being contaminated and damaged, ensuring stable product quality.

-

Pharmaceutical Industry

- Liquid Medicine Transportation: In the pharmaceutical manufacturing process, twin – screw pumps are used to transport various liquid medicines, including those containing active ingredients, colloids, or suspended particles. The low – shear – force can prevent the active ingredients of the medicine from being damaged, ensuring the quality and efficacy of the medicine. The high – precision flow control meets the requirements of accurate ingredient dispensing in pharmaceutical production.

- Transportation of Semi – solid Preparations such as Ointments and Gels: For semi – solid pharmaceutical preparations such as ointments and gels, twin – screw pumps can overcome their high viscosity and achieve smooth transportation from the mixing equipment to the filling equipment without affecting the uniformity and stability of the preparations.

-

Construction and Building Materials Industry

- Construction Coating Transportation: In paint manufacturing plants and construction sites, twin – screw pumps are used to transport various construction coatings, such as latex paint and waterproof paint. Their stable flow output ensures the uniformity of the coating during production mixing and construction spraying, improving the construction quality of the coating.

- Transportation of Cement Mortar and Grouting Materials: In construction, twin – screw pumps can be used to transport materials such as cement mortar and grouting materials. They can provide sufficient pressure to transport the materials to high places or long distances, meeting the construction needs of building structure reinforcement and foundation treatment.

-

Shipbuilding Industry

- Ship Fuel Transportation: In the ship’s power system, twin – screw pumps are responsible for transporting fuel from the storage tank to the engine. Their good self – priming ability ensures stable fuel supply even when the ship is bumping and the fuel level changes. Their characteristic of adapting to different viscosities of fuel meets the needs of ships using various types of fuel.

- Lubricating Oil Transportation: In the ship’s equipment lubrication system, twin – screw pumps transport lubricating oil to various parts that need lubrication to ensure the normal operation of ship mechanical equipment. Their smooth operation and low – noise characteristics meet the requirements of the ship’s engine room for equipment operation stability and noise control.

-

Environmental Protection Industry

- Sewage Treatment: In sewage treatment plants, twin – screw pumps can transport sewage and sludge containing solid particles and fibers. Their strong self – priming ability allows them to draw sewage from different locations, and their wear – resistant characteristics enable them to operate stably for a long time in a harsh sewage environment.

- Industrial Wastewater Treatment: For various industrial wastewaters generated during industrial production, twin – screw pumps are used to transport the wastewater to treatment equipment for purification. Their adaptability to different types of wastewater ensures the smooth progress of the wastewater treatment process.