Description

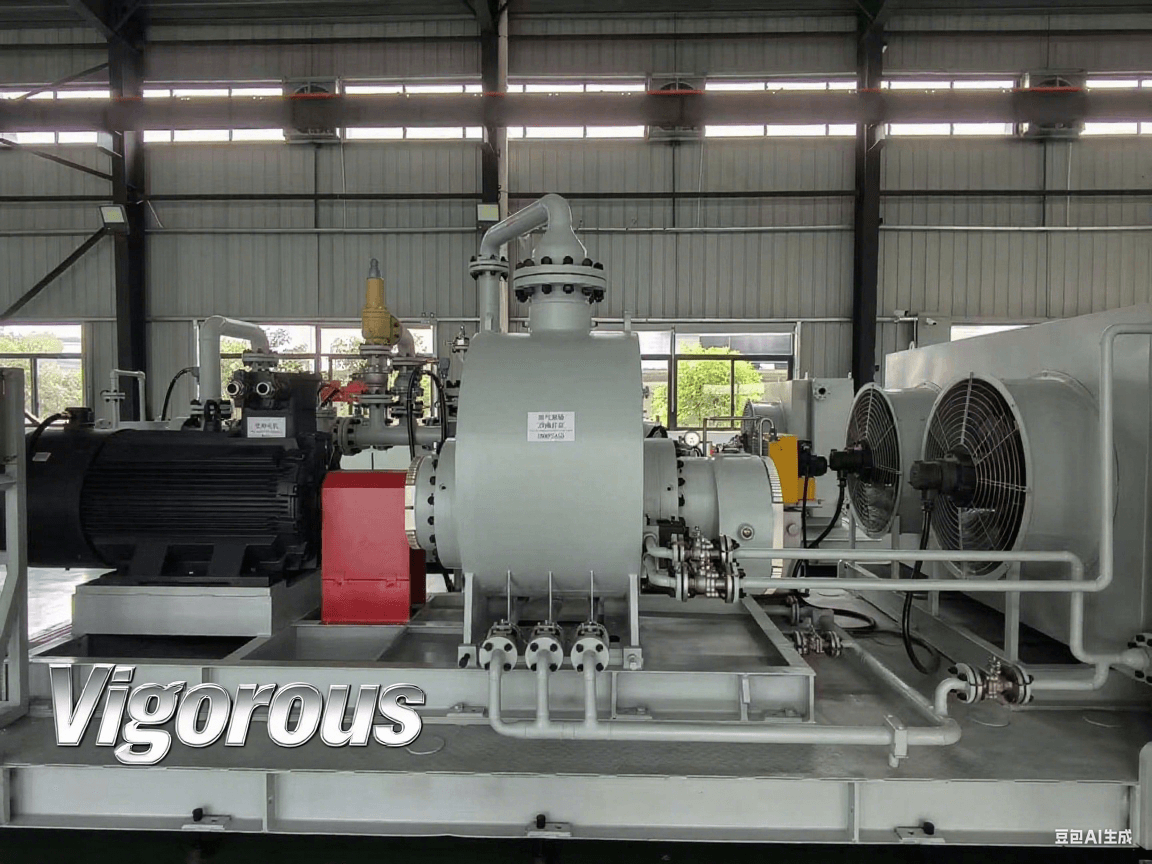

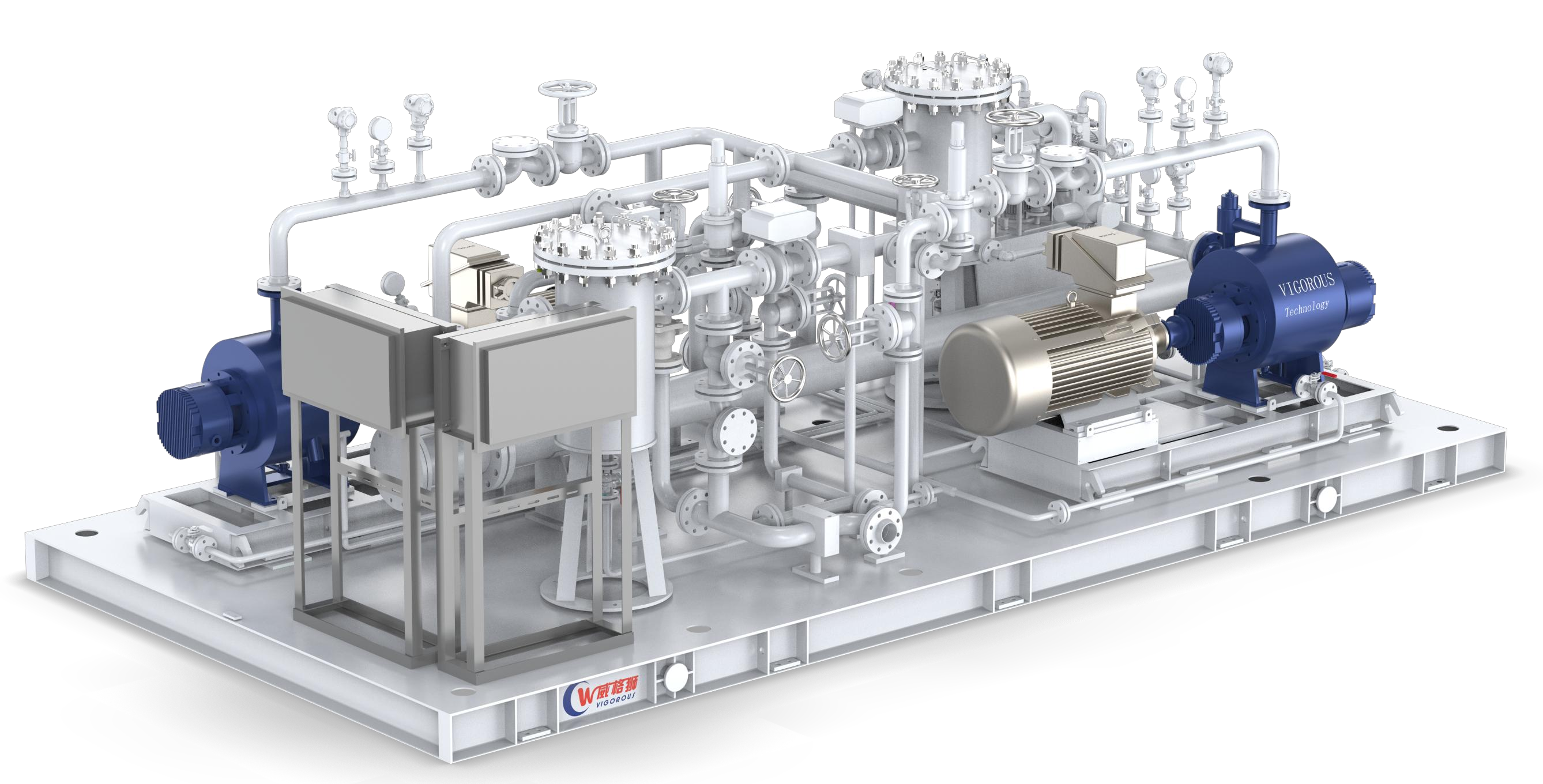

Intelligent Pump Skid System HWMPS450 for Water-Flooded & CBM Wells | Slug Flow Handling + Gas-Liquid Mixed Transportation

I. Product Overview

- Pump Skid Name: Intelligent Pump Skid System for Water-Flooded and CBM Well Exploitation

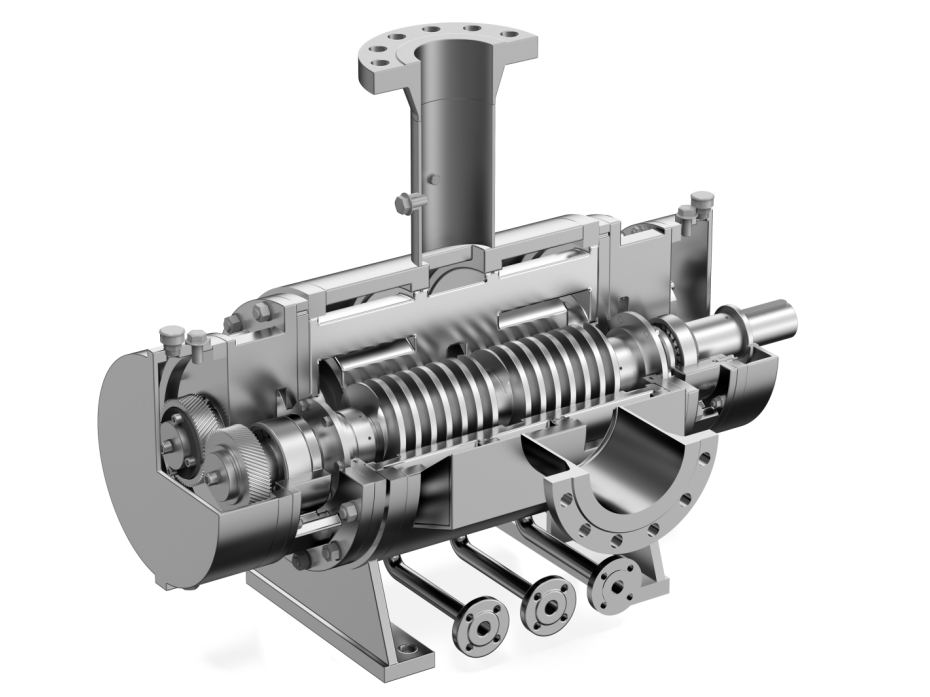

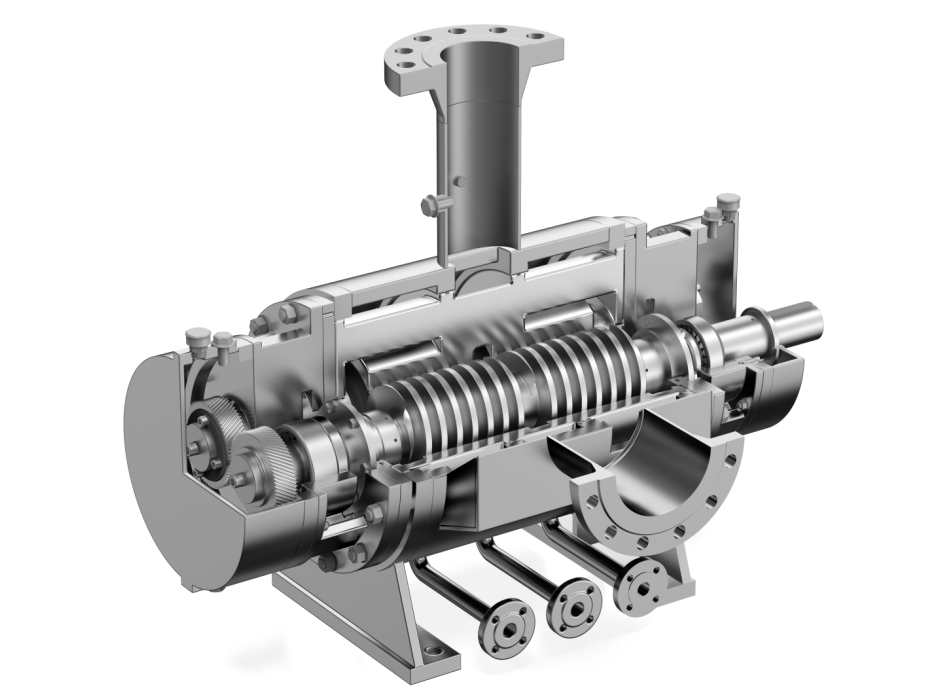

- Main Pump Model: HWMPS450

- Core Advantage: “centrifugal pump + compressor” integrated design, enabling continuous transportation of 100% gas, 100% liquid, or any gas-liquid mixture. Solves slug flow challenges in water-flooded and CBM wells, with equipment costs 30% lower than traditional solutions.

II. Key Functional Features

-

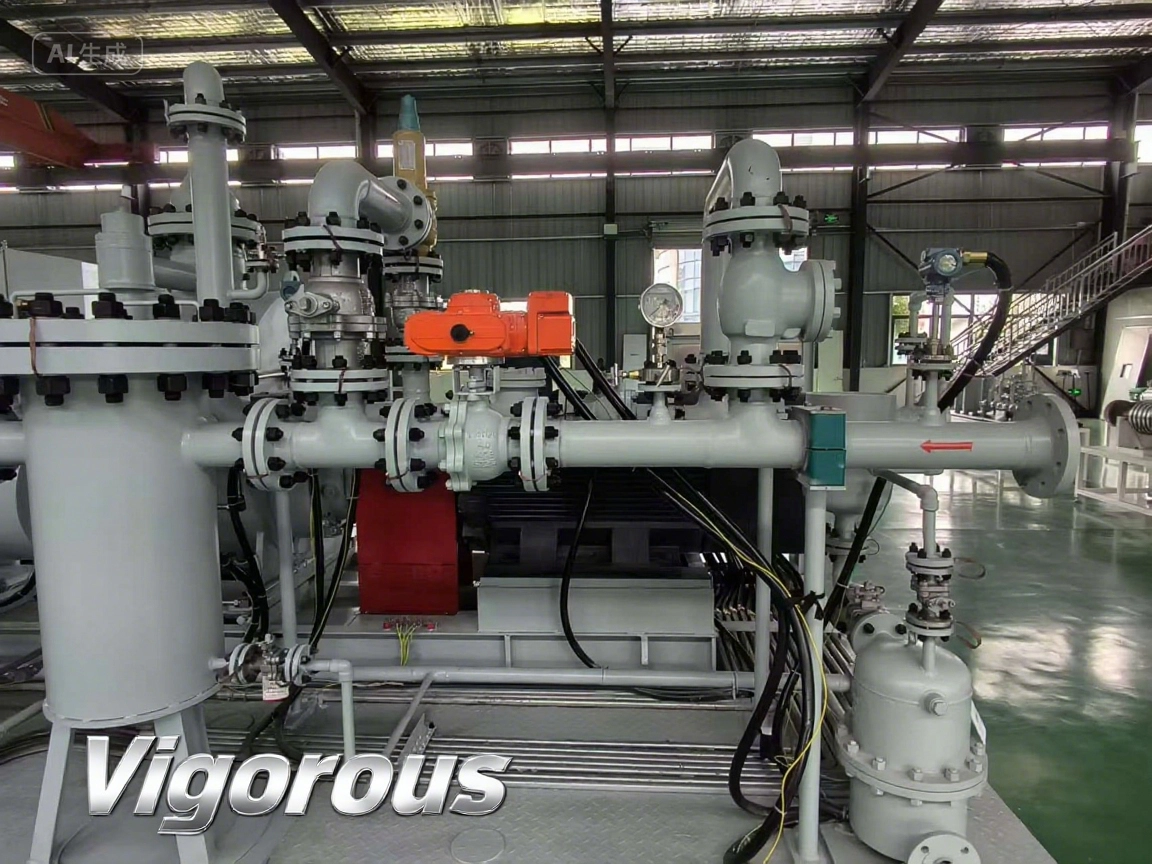

Superior Gas Compression & Pressure Control

- 40% higher gas compression ratio, outlet pressure balance control precision of ±0.1MPa, suitable for high-gas CBM wells (methane content ≥90%).

- Keywords: gas compression capability, outlet pressure balance, CBM exploitation

-

Long-Term Slug Flow Handling Technology

- Built-in dynamic buffer chamber and flow adaptive adjustment system processes slug flow with gas-liquid ratios from 10:1 to 1:10 without shutdown (traditional solutions have >25% downtime).

- Keywords: slug flow handling, dynamic buffer chamber, water-flooded well exploitation

-

Low-Cost & High-Reliability Design

- Modular skid structure reduces installation costs by 50%, with 40% lower full-life maintenance costs, adapting to large-scale oilfield transformation needs.

- Keywords: equipment investment cost, modular skid, oilfield application

III. Application Scenarios & Market Potential

1. Target Application Scenarios

- Water-flooded Well Recovery: Rehabilitation of over 5,000 water-flooded wells in Changqing Oilfield and 3,000+ low-efficiency wells in Xinjiang Oilfield

- CBM Exploitation: High-gas CBM wells (gas content ≥85%) in Qinshui Basin and Ordos Basin

- Keywords: water-flooded well recovery, CBM well, Ordos Basin

2. Market Scale Data

- Over 100,000 existing water-flooded wells and 5,000+ annual new CBM wells in China, with market size expected to exceed ¥120 billion by 2025

- Verified case: In a Southwest Oilfield block, HWMPS450 reduced single-well exploitation costs by 28% and increased gas production efficiency by 35%

- Keywords: billion-level market, Changqing Oilfield, Southwest Oilfield

IV. System Technical Innovations

-

Integrated Gas-Liquid Mixed Transportation Design

- Combines liquid transportation capacity of centrifugal pumps with gas pressurization of compressors, supporting seamless switching between full-gas (100%) and full-liquid (100%) operations.

- Keywords: gas-liquid mixed transportation, seamless switching, integrated design

-

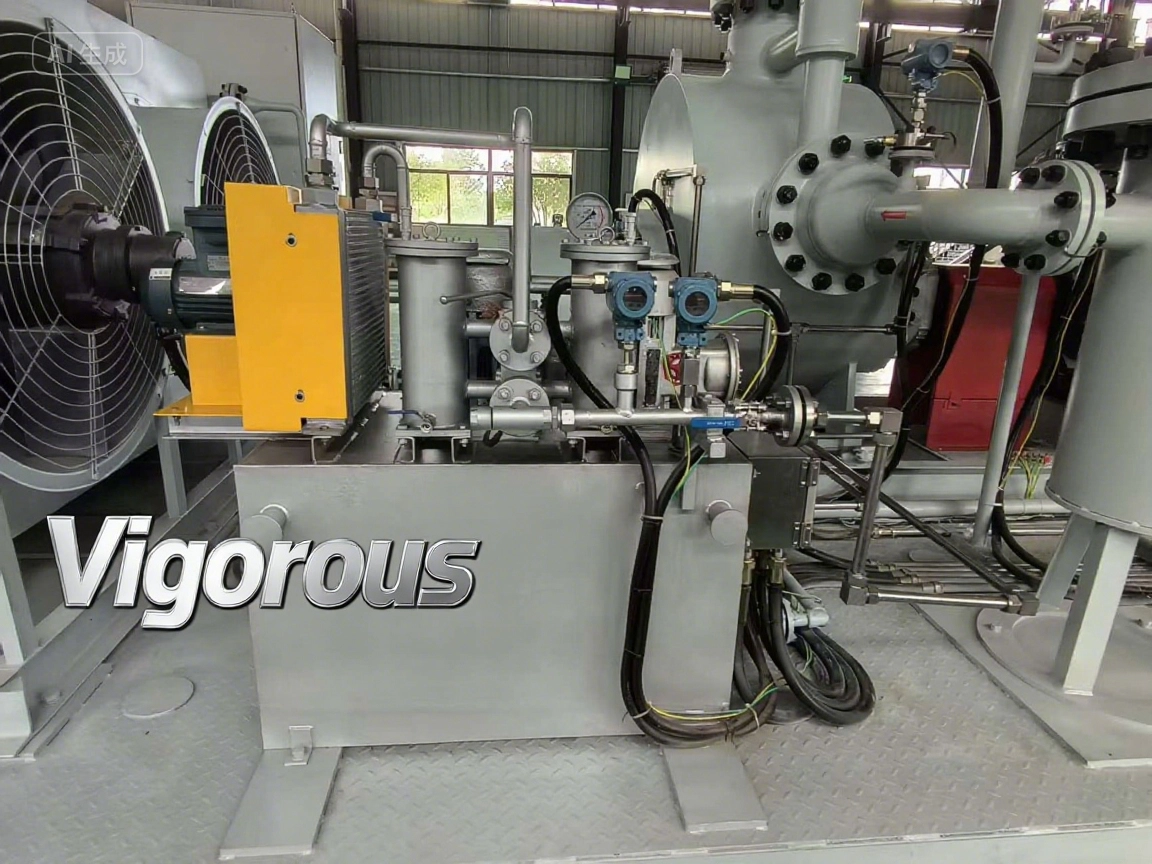

Intelligent Cooling & Fluid Replenishment System

- External automatic fluid replenishment cooling circuit + air-cooled heat exchanger combination monitors pump body temperature (controlled ≤75℃), adapting to heat dissipation needs in high-gas conditions.

- Keywords: automatic fluid replenishment, air-cooled heat exchanger, temperature control

-

Slug Flow Uninterrupted Operation Solution

- Optional heat exchanger/cooling tank cooling module adjusts fluid replenishment via PLC intelligent control, solving the industry challenge of “gas expansion endothermic – equipment overheating”.

- Keywords: PLC intelligent adjustment, cooling module, industry challenge