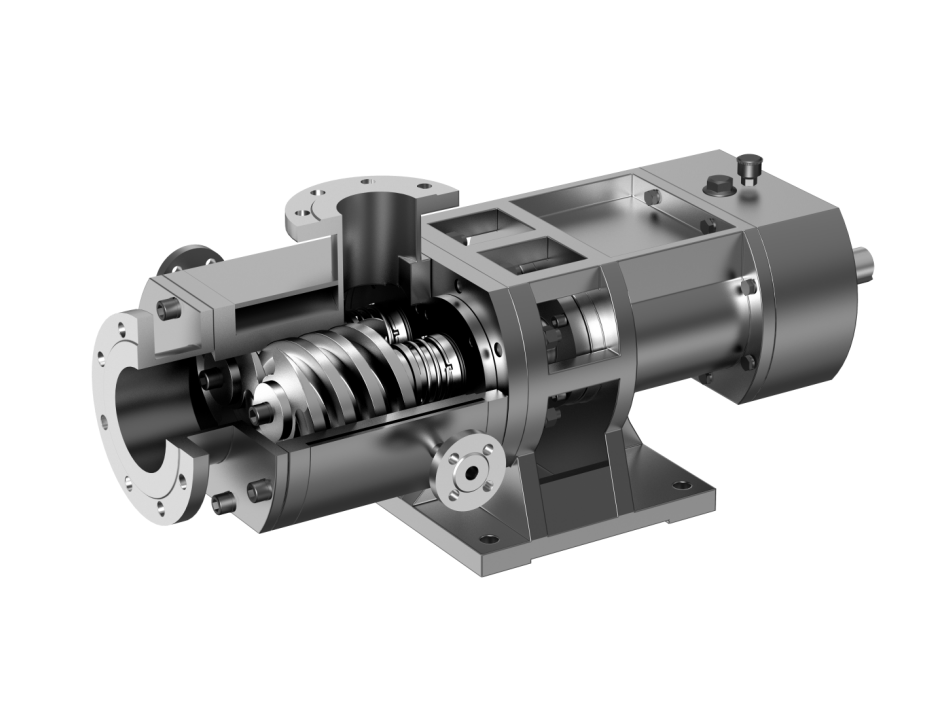

As a rotary positive displacement pump, the working principle of a twin screw pump is based on the efficient conveyance of materials along the axes of two screws. Between the two non contacting and meshing screws and the pump housing, a series of closed cavities are formed. When the pump is in operation, these cavities can continuously push the materials from the suction port to the discharge port.

The twin – screw pump is highly flexible in controlling the conveying direction. Thanks to the unique arrangement of the pump components, simply reversing the rotation direction of the pump shaft can reverse the conveying direction of the materials. This axial conveying method enables the materials to maintain a smooth and low – pulsation state during the pumping process. For materials that are sensitive to shear force, the twin – screw pump has significant advantages. The materials hardly bear additional stress during the conveying process, thus effectively ensuring that the volume, appearance, and characteristics of the medium remain unaffected.