On the complex stage of shipping operations, screw pumps, with their unique performance, have become reliable workhorses for transporting various chemical media. From high – viscosity industrial greases to special liquid resins, screw pumps demonstrate extraordinary adaptability. Next, let’s delve into the characteristics of common chemical media and the significant advantages of twin – screw pumps and three – screw pumps in transporting them.

I. The Viscosity Code of Chemical Media and Transportation Challenges

1. Industrial Greases

Industrial greases, regarded as the “blood” of mechanical equipment, are crucial in fields such as ship power systems. Taking the typical ISO VG 100 industrial gear oil as an example, at a working temperature of 40°C, its kinematic viscosity is approximately 100 cst. This viscosity not only enables industrial greases to provide lubrication and protection but also poses certain requirements for transportation equipment. During shipping, it needs to be accurately and efficiently transferred from storage tanks to various lubrication points or storage containers on the ship to ensure the smooth operation of ship equipment.

2. Heavy Oil

As the “energy source” of ship power, the high viscosity of heavy oil is its prominent feature. For instance, the common 380 cSt heavy oil has a kinematic viscosity as high as 380 cst at 50°C, which vividly reflects the difficulty of heavy – oil transportation. During the shipping process, not only the resistance brought by its high viscosity needs to be overcome, but also the stability of the transportation process must be ensured to meet the large – scale fuel demand of ships during long – distance voyages.

3. Asphalt

Asphalt, which plays a key role in road construction and waterproofing, is a challenging medium to transport. At a heated state of 135°C, its kinematic viscosity generally ranges from 300 – 600 cst. The high viscosity and easy – to – solidify characteristics of asphalt require that the shipping pump must have special designs and performance to ensure that its quality and performance are not affected during transportation.

4. Liquid Resins

Liquid resins, such as epoxy resins and unsaturated polyester resins, are widely used in the composite materials and coatings industries. Taking unsaturated polyester resin as an example, at 25°C, its kinematic viscosity is approximately between 200 – 600 cst. These resins are sensitive to shear force. During shipping, excessive shear must be avoided to maintain their chemical and physical properties and ensure the quality of the final product.

5. Chemical Raw Materials

Chemical raw materials like polyethylene glycol 400 and glycerol have unique viscosity characteristics. Polyethylene glycol 400 has a kinematic viscosity of about 40 cst at 20°C, and glycerol has a kinematic viscosity of about 1490 cst at the same temperature. Different viscosities mean that different pumping strategies are needed during shipping to adapt to their respective physical and chemical properties.

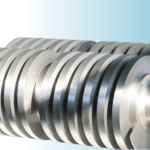

II. Twin – Screw Pumps: Conquerors of High – Viscosity and Complex Media

1. Gentle “Carriers” for High – Viscosity Media

For high – viscosity media such as industrial greases, heavy oils, and asphalt, twin – screw pumps are “experts”. Their unique twin – screw structure, with two screws meshing with each other to form multiple sealed chambers. When transporting 380 cSt heavy oil, this structure can provide stable transportation power while applying gentle shear force to the medium. Compared with other pump types, twin – screw pumps can better maintain the original characteristics of heavy oil, ensuring that the fuel quality is not affected and laying the foundation for the stable operation of the ship’s power system.

2. Flexible Dancers in Flow Regulation

Twin – screw pumps exhibit extremely high flexibility in flow regulation. During the shipping process, in the face of different shipping progress requirements, operators can achieve precise flow control simply by adjusting the pump’s rotation speed. For example, when transporting ISO VG 100 industrial gear oil, whether it is for rapid shipping to improve efficiency or slow shipping to ensure accuracy, twin – screw pumps can handle it easily, just like a flexible dancer, adjusting its steps precisely according to the command.

3. Convenience Brought by Self – Priming Ability

The self – priming ability of twin – screw pumps is a major highlight in shipping operations. In actual operation, without the cumbersome pump – priming procedure, it can smoothly suck in the chemical media from the low – lying storage tanks and transport them to the ship by virtue of its own self – priming function. This feature not only simplifies the shipping process but also saves time and labor costs, especially suitable for some shipping scenarios with high installation positions or limited spaces.

4. Tough Guards Resistant to Impurities

Considering that some industrial greases and chemical raw materials may contain a small amount of impurities, the wide flow channels and simple structural design inside the twin – screw pump enable it to have a certain degree of impurity tolerance. Even when transporting industrial lubricating oils containing trace solid particles or fiber impurities, the twin – screw pump can still operate stably, effectively avoiding transportation interruptions caused by impurity blockages, just like a tough guard, safeguarding the smooth progress of the shipping operation.

III. Three – Screw Pumps: The Perfect Combination of Precision and Efficiency

1. Precision Masters with Stable Flow

For media such as liquid resins and polyethylene glycol that have almost stringent requirements for flow stability, three – screw pumps are undoubtedly the best choice. Their unique three – screw design enables the pump to output an extremely smooth flow during operation, with almost imperceptible flow pulsation. When transporting unsaturated polyester resin for manufacturing high – end composite materials, the stable flow of the three – screw pump ensures the uniform distribution of the resin in the composite material, thus significantly improving the quality and performance of the product, just like a precision master, precisely controlling every detail.

2. Efficient and Energy – Saving Pioneers in Transportation

When transporting low – to – medium – viscosity chemical raw materials, three – screw pumps demonstrate excellent efficiency. Taking polyethylene glycol 400 as an example, its relatively low kinematic viscosity (about 40 cst at 20°C) enables the three – screw pump to achieve efficient transportation with minimal energy loss. The screw design of the three – screw pump optimizes the hydrodynamic performance, reducing internal energy losses. While reducing the shipping operation cost, it improves the transportation efficiency, making it an efficient and energy – saving pioneer in shipping operations.

3. Silent Messengers with Quiet Operation

During the operation of the three – screw pump, the balanced design of the interaction force between the screws results in extremely low noise and vibration. At the shipping operation site, this low – noise and low – vibration feature not only creates a more comfortable working environment for the staff but also avoids interference with other sensitive equipment on the ship. Whether in a quiet port environment or an operation area with strict noise control, the three – screw pump can, like a silent messenger, complete the transportation task silently.

4. Reliable Partners with Long – Lasting Durability

The three – screw pump generates relatively small axial force during operation, which greatly reduces the load on key components such as bearings. This low – load operation state effectively slows down the wear rate of components, thus significantly extending the overall service life of the pump. In long – term shipping operations, the three – screw pump, with its reliable performance and minimal maintenance requirements, has become a trusted partner of operators, providing strong support for the continuity and stability of shipping operations.