Under the complex working conditions of oilfield multiphase flow, Vigorous multiphase pumps effectively solve a series of transportation problems with their excellent performance and elaborate design.

Characteristics of Multiphase Flow Working Conditions and Pump Adaptability

Oilfield multiphase flow starts from the wellbore and extends to the first – stage separator of the central processing facilities. It’s in a transient state throughout, prone to slug flow. The gas volume fraction (GVF) of multiphase flow varies greatly, from 0 to 100% (from pure liquid phase to pure gas phase). The farther from the wellhead or manifold, the longer the gas – phase section. Vigorous multiphase pumps fully consider these working – condition features. Their design can adapt to such extreme GVF changes. They’re especially suitable for installation near the fluid outcrop on the surface or at the manifold. Even facing complex flow patterns, they can ensure stable operation through a reasonable system design.

Coping with Challenges of Transporting Different Media

1. Avoiding Overheating in Dry Gas or High – GVF Conditions

Most pumps aren’t suitable for dry gas or 100% GVF conditions. Otherwise, overheating easily causes “flow interruption”. But Vigorous multiphase pumps, with special designs like internal or external recirculation systems, lower the GVF to a manageable range. This ensures continuous operation under any fluid composition. This design can handle multiphase production scenarios such as rich – gas and lean – gas, and avoid overheating shutdowns caused by dry gas or high GVF.

2. Handling Oil Wells with High Liquid Content

Compressors can’t effectively handle the increased liquid in oil wells with high water production. Vigorous multiphase pumps, however, have significant advantages in such conditions. They can stably transport gas – liquid mixtures, meeting the production needs of oil wells with high liquid content.

Cooling and Anti – Dry – running Measures

1. Using Internal Characteristics for Auxiliary Cooling

The screws and flow channels in Vigorous multiphase pumps have a non – contact feature. Part of the pumped fluid bypasses the pressurization process and returns to the inlet side, but the potential liquid holdup of this part of the fluid helps cool the pump body.

2. External Liquid – assisted Cooling

Manufacturers suggest using a downstream – separated liquid source to prevent dry – running and avoid overheating shutdowns. These liquids can come from an independent downstream (or upstream) container or the pump – casing chamber on the pump outlet side. By continuously recirculating the separated liquid at a ratio of 3% to 5% of the total pump flow rate, although the pump efficiency is slightly reduced, it can effectively limit the process temperature rise, avoid local overheating, and ensure stable operation when transporting a 100% GVF constant fluid.

Solid and Sediment Control

1. Up – stream Filtration

Sand production in oil – gas wells is an industry – wide problem. Solids can wear surface equipment, especially twin – screw pumps. Due to the extremely small gap between the screw and the bushing, twin – screw pumps are more vulnerable. Vigorous multiphase pumps install a simple single – tank filtering device upstream of the pump, successfully removing all flowing particles larger than 70 microns and reducing the damage of solids to the pump from the source.

2. Surface Protection

To further extend the pump’s service life, the top of the screw and the inner hole of the bushing are surface – hardened or coated. For example, tungsten carbide is sprayed on the top of the screw, and a hard – chromium layer is plated on the inner hole of the bushing. If the produced fluid contains CO₂ and H₂ S, similar protection is fully considered in material selection. This effectively enhances the wear resistance of the inner surface, avoids replacing the internal components of the pump in the short term, and ensures the sustainable and stable operation of the pump.

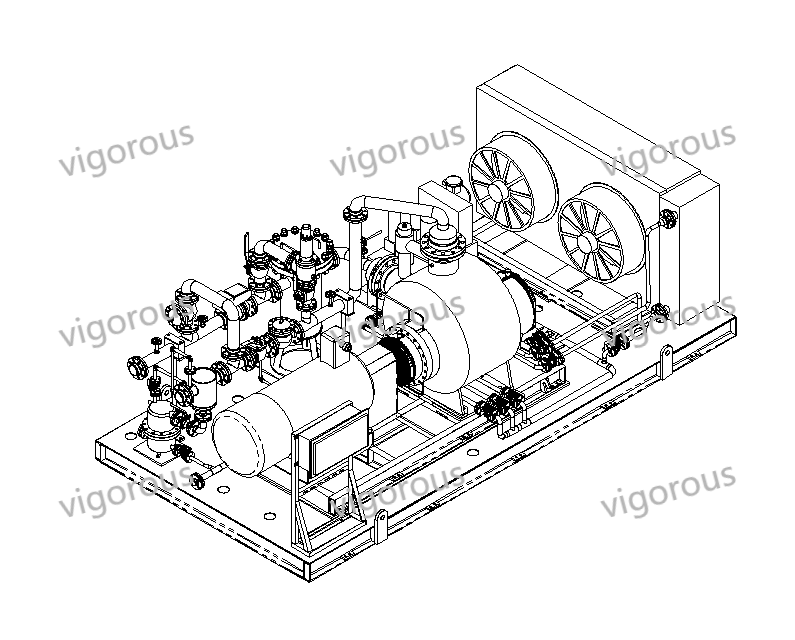

Advantages of the Twin – screw Multiphase Pump System

As a positive – displacement device, the Vigorous twin – screw multiphase pump system can operate independently of changes in fluid density, inlet pressure, back pressure, and GVF. It works with the help of an inlet separator and an internal recirculation system. The system is designed specifically to deal with slug flow and its operation isn’t affected. At the same time, it can handle high – GVF and wet – gas conditions through integrated liquid recirculation. For lean – gas flow (100% GVF) conditions, it’s also equipped with a cooler to remove the compression heat. During the oilfield life cycle, the multiphase flow can be controlled by adjusting the pump speed to meet the needs of various production scenarios. It’s an ideal choice for handling multiphase production up to 100% GVF.