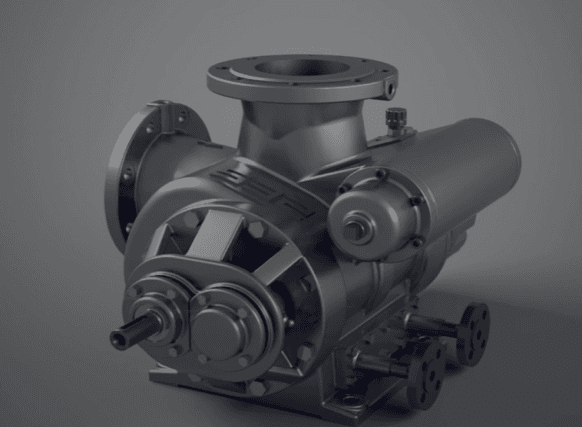

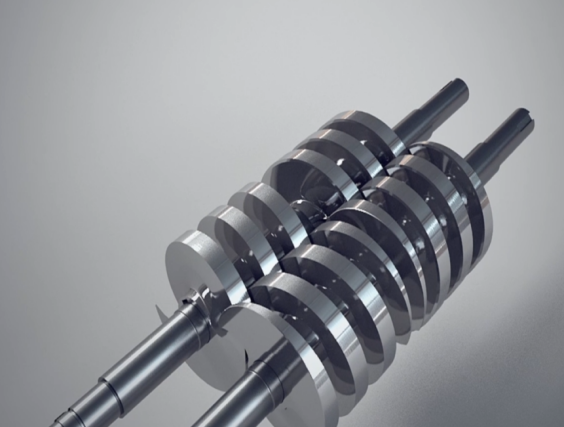

Screw pumps are positive displacement rotor pumps. my country’s screw pumps were first introduced and produced in the 1960s, nearly 20 years later than the development of foreign screw pump technology. However, with the continuous development of the economy, my country has conducted in-depth research on foreign advanced technologies and developed twin-screw pumps, three-screw pumps, and five-screw pumps. Due to its unique structure, self-priming ability, high efficiency, small size, reliable operation, and ability to transport a wide range of media with a wide viscosity range, screw pumps are widely used in industrial sectors such as petrochemicals, shipping, electricity, mechanical pressure systems, food, papermaking, and sewage treatment.

The causes of twin-screw pump failures are usually caused by many factors, and different failures show different phenomena. To troubleshoot, the cause of the failure must be found out first. In practice, through scientific research, prediction, and analysis, the abnormal performance of the twin-screw pump can be found, problems can be solved, and failures can be eliminated. The general principle for judging twin-screw pump failures is: combining structure, connection principles, clarifying phenomena, combining reality, from simple to complex, from the outside to the inside, by system segmentation, and finding causes.

After long-term operation of the twin-screw pump, abnormal failures usually occur, and the following phenomena are usually encountered.

1. The pump body vibrates violently or generates noise. Reasons: The pump is not installed firmly, the pump is installed too high, exceeding the pump suction capacity; the motor ball bearing is damaged; the water pump main shaft is bent or is not concentric or parallel with the motor main shaft, etc.; the suction pipe or pump suction end leaks; the suction pipe is blocked.

The solution is to install the water pump steadily or lower the installation height of the water pump, reduce the resistance of the suction pipe, clean or increase the filter, and reduce the viscosity of the medium; replace the motor ball bearing; correct the bent water pump main shaft or adjust the relative position of the water pump and the motor; eliminate the air leakage of the suction pipe and the pump suction end; eliminate the blockage of the suction pipe.

2. The cause of overheating of the drive shaft or motor bearing: lack of lubricating oil or bearing rupture, etc.

The solution is to add lubricating oil or replace the bearing.

3. Pump heating: severe friction of rotating parts in the pump; blockage of the oil return hole of the mechanical seal; excessive oil temperature; improper installation, non-concentric rotating parts.

The solution is to check and replace the worn parts; dredge the oil return hole; appropriately reduce the oil temperature; adjust and correct the assembly and installation accuracy. 4. No flow output: the suction pipeline is blocked or leaking; the suction height exceeds the allowed suction vacuum height; the motor reverses; the medium viscosity is too large, etc. The solution is to check the suction pipeline, reduce the suction height, change the motor direction, heat the medium, etc. 5. Insufficient pump pressure: whether the seal is leaking; when the equipment is stopped, when the screw pump still has a self-closing function, check with water; whether the selection is correct; the pressure at the outlet is too high, etc., the pump pressure is insufficient. There are many problems involved. The simplest is to check whether the inlet is blocked, and then look at the motor. If these two are fine, then you have to open it to see if the screw and bearing are broken. 6. Flow rate decrease: the suction pipeline is blocked or leaking; the spiral sleeve and bushing are worn; the safety valve spring is too loose or the valve disc is not in close contact with the valve seat; the motor speed is not enough; the installation is too high, exceeding the pump suction capacity, and the shaft seal leaks. The corresponding solution should be to inspect the suction pipeline; replace parts when the wear is serious; adjust the spring, grind the valve disc and the valve seat; repair or replace the motor; reduce the suction height and the resistance of the suction pipeline; inspect or replace the shaft seal.

7. Mechanical seal leaks a lot of oil: the assembly position is wrong; the sealing cover is not flattened; the dynamic ring or static ring sealing surface is bruised; the dynamic ring or static ring sealing ring is damaged.

The solution is to reinstall as required; adjust the sealing cover; grind the sealing surface or replace new parts; replace the sealing ring.

8. Mechanical seal heating: the sealing liquid pipeline is blocked; the mechanical seal spring compression is too large.

The solution is to eliminate the sealing pipeline failure; reduce the spring compression.

9. The shaft power increases sharply: the discharge pipeline is blocked; the screw and the pump sleeve are seriously rubbed; the medium viscosity is too large; the installation is not correct, and the rotating parts are not concentric.

The solution is to stop the pump to clean the pipeline; inspect or replace related parts; heat up the medium to reduce the viscosity; adjust and correct the assembly and installation accuracy.

10. Seizing the shaft (cannot rotate): The temperature is too high and the parts inside the pump expand excessively; the starting torque is insufficient.

The solution is to turn the pump by hand after it cools down and then start it; check the drive device.

When the twin-screw pump is running, after the above abnormal phenomena are found, a careful investigation must be carried out, and the location and cause of the fault must be analyzed and judged according to the fault phenomenon. Sometimes there may be several abnormal phenomena for one fault, and sometimes one abnormal phenomenon may be caused by several faults. Therefore, when abnormal phenomena occur during the operation of the twin-screw pump, the cause of the abnormal phenomenon must be carefully investigated, which requires us to be good at analysis, reasoning and judgment, grasp the essence through the phenomenon, and find out the cause and location of the fault according to the abnormal phenomenon, and eliminate the fault.

The application scope and field of screw pumps are getting larger and larger, and the technical requirements for them are getting stricter and stricter, so it should be the focus of future research to study screw pumps suitable for different types. The market prospect of twin-screw pumps is very broad. However, since the reliability of twin-screw pumps needs to be further strengthened, improving the technical content of twin-screw pump products is the main direction for the future development of screw pump manufacturers.

2 Comments

"The Magical Application of Double Screw Pumps in Multiple Fields" - Weigeshi Pump IndustryCo., Ltd.

[…] sealing performance, ensures that the media are not contaminated and complies with industry norms.2.Advantages of Double Screw Pumps Double screw pumps have a stable flow rate. No matter how the properties of the medium and working […]

Screw Pumps: The Premier Choice for Shipping Chemical Media - Weigeshi Pump IndustryCo., Ltd.

[…] delve into the characteristics of common chemical media and the significant advantages of twin – screw pumps and three – screw pumps in transporting […]