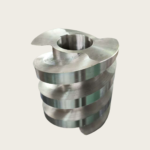

1. Screw Replacement Judgment

- Gap Check: Use a feeler gauge to measure the gap between the two screws. If the gap exceeds 0.2mm, replacement is needed. A too-large gap will make the pump deliver less material and wear faster.

- Surface Condition: Check for obvious scratches, pits, or cracks on the screw surface. If the depth of these defects exceeds 0.1mm, or if there are continuous wear marks longer than 5cm, replace the screws promptly.

- Functional Impact: If the pump’s output decreases by more than 15% (compared to the new pump), and cleaning the filter or adjusting the speed doesn’t help, it may be due to excessive screw wear requiring replacement.

2. Gearbox Component Replacement

- Gear Wear: Open the gearbox and check the gear teeth. If there are signs of chipping, uneven wear, or “point-like” damage on the tooth surface, replace the gears.

- Oil Quality Inspection: If the gear oil turns black, has sediment, or emits a burnt smell, drain and replace it immediately. If new oil deteriorates quickly (within 500 hours of use), check for gear wear that may be contaminating the oil.

- Abnormal Noise: A continuous “clicking” or “grinding” sound from the gearbox during operation indicates poor gear engagement. After confirming no loose parts, replace the gears.

3. Bearing and Seal Replacement

- Bearing Temperature: During operation, if the bearing housing temperature exceeds 70°C (measured with a thermometer) and remains high after cooling, the bearing is worn and needs replacement.

- Seal Leakage: If the mechanical seal leaks more than 10 drops per minute, or if there’s obvious oil leakage from the bearing housing, replace the seal components.

- Rotation Smoothness: When manually rotating the pump shaft, if there’s obvious jamming or uneven resistance (excluding normal startup friction), the bearing may be damaged and require replacement.

4. Stator Liner Replacement

- Inner Surface Damage: Check the metal stator liner for scratches, corrosion pits, or uneven wear. If the damaged area covers more than 10% of the inner surface, replace the liner.

- Fit with Screws: If the stator liner and screws rub abnormally during operation (accompanied by harsh noise), and adjusting the gap doesn’t resolve it, replace the liner.

5. Replacement Cycle Reference

- Screws: Generally, replace every 8,000–12,000 hours (shorten to 5,000–8,000 hours for high-sand or corrosive materials).

- Gears and Bearings: Replace every 10,000–15,000 hours, or earlier if abnormal sounds or temperature rises occur.

- Seals: Replace every 6,000–8,000 hours (or immediately if leakage exceeds the standard).