As a representative oilfield for ultra-deep and extra-heavy oil development in China, Tahe Oilfield is Tahe Oilfield is a leader in ultra-deep, extra-heavy oil development in China. Its crude oil is notoriously hard to transport. At room temperature, it acts like asphalt. It has poor fluidity, high water content, and lots of sand. This puts tough demands on transportation equipment.

Early on, problems like frequent jams, leaks, and wear were common. Now, twin screw pumps enable stable, efficient operation. Their use in Tahe is a “precision adaptation battle” against extreme conditions. Vigorous’ twin screw pumps, with key performance strengths, are a major player in this effort.

I. Challenges in Tahe Crude Oil Transportation: Traditional Equipment Shortcomings

Tahe’s crude oil has stumped traditional transport gear. This highlights why twin screw pumps matter:

- Extra-heavy oil “freezes up”: At room temperature, the oil is almost solid. Traditional centrifugal pumps block instantly when started. Single screw pumps lose efficiency fast. Heavy oil gets stuck in their chambers. Twin screw pumps’ design solves this.

- High water content tests seals: As oil extraction progresses, water content rises. Conventional pump seals break down quickly in water. This means frequent shutdowns for replacements. Twin screw pumps need better sealing tech to handle this.

- Sand causes wear: Sand in the crude grinds down pump parts. This shortens equipment life and raises maintenance costs. Twin screw pumps need wear-resistant designs to cope.

II. Twin Screw Pumps: Solving Tahe’s Unique Problems

Twin screw pumps work in Tahe’s tough conditions thanks to targeted upgrades. Three key improvements stand out:

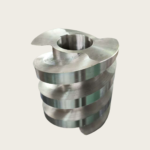

1. Custom Designs for Extra-Heavy Oil

Twin screw pumps have optimized rotor helix angles and lead lengths. This lets heavy oil flow more easily through the pump. It reduces clogs and stops jams. Now, extra-heavy oil transport is steady, not a struggle.

2. Tougher Materials Fight Wear and Rust

Twin screw pumps use wear-resistant, corrosion-proof materials. Rotors get special coatings. Seals resist water. This makes the pumps handle sandy, water-rich oil better. They need less maintenance and last longer.

3. Smart Features Cut Maintenance Work

Twin screw pumps have temperature controls and anti-clog systems. These stop heavy oil from freezing in cold conditions. Less manual work is needed. The pumps are easier to maintain, even in tough conditions.

III. Vigorous Twin Screw Pumps: Tahe Oilfield’s “Reliable Partner”

Vigorous’ twin screw pumps are core equipment in many Tahe blocks. Their ability to adapt makes them stand out. Key benefits include:

- Works in extreme conditions: Tahe’s oil is extra-heavy, wet, and sandy. Vigorous designed its twin screw pumps specifically for this. Rotors and materials are tailored. The pumps run steady in complex oil. No frequent shutdowns for fixes.

- Lasts longer, saves hassle: Vigorous uses wear-resistant coatings and rust-proof seals. Its twin screw pumps outlast standard models in Tahe. This cuts maintenance needs and lowers costs.

- Adapts to different needs: Oil varies between Tahe’s blocks. Viscosity and sand levels differ. Vigorous’ twin screw pumps adjust easily. They work well from wellhead collection to joint station transport.

Tahe’s experience proves twin screw pumps are ideal for extra-heavy oil transport. Vigorous understands extreme conditions deeply. Its technical expertise makes twin screw pumps in Tahe more efficient and reliable. It’s a key force supporting Tahe’s ongoing development.

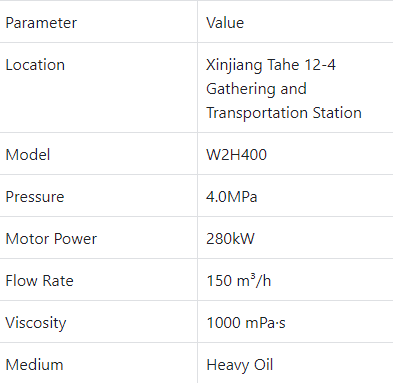

The parameters of this project:W2H400