- A Brief Analysis of Wear – Resistant Coating Technology for Metal Components

Reading Tip: This article will explain industrial – grade “coating” technology in plain language, helping you understand the secrets of how screw pumps combat wear.

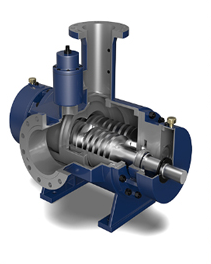

I. When Metal Screws Encounter Sand Grains: A War in the Micro – World

IImagine two closely – meshed metal gears spinning in sand grains:

Sand grains are like tiny blades. Quartz sand, much harder than metal (similar to glass in hardness), keeps cutting the screw surface.

Corrosion adds to the trouble. Acidic media act like “invisible files” to speed up metal loss.

The gap gets out of control. It’s like sand getting stuck between watch gears, and the precise fit gradually fails.

Real – world example: In a chemical plant, when transporting a medium with 15% quartz sand, untreated screws showed obvious grooves after just 6 months, causing a 35% drop in pump efficiency.

II. Three Ways to “Arm” Metal

II. Three Ways to Put “Armor” on Metal

- Selection of Armor Materials

“A combination of rigidity and flexibility”:

Surface layer: Super – hard tungsten carbide (similar to diamond micropowder) resists cutting.

Transition layer: Cobalt – containing materials act like “elastic pads” to buffer impacts.

Base: Retain the original toughness of the steel.

Analogy of the coating structure

- High – velocity Oxygen – Fuel (HVOF) Spraying Technique

It’s like “spraying cermet with a flamethrower”:

Heat the alloy powder to a semi – molten state (about 3000℃).

“Spray” it onto the screw surface at supersonic speed.

Cool it instantly to form a dense protective layer.

Key Advantage: The substrate temperature does not exceed 180℃ (similar to oven temperature), avoiding component deformation.

- Precise “Make – up” Process

Precise coverage: The robotic arm controls the spraying, with an error less than the diameter of a human hair (±0.05mm).

Thickness control: It’s equivalent to evenly covering the metal surface with the thickness of 3 A4 papers (about 0.12mm).

Post – refinement: Polish it like carving jade to ensure meshing accuracy.

III. Practical Results: From Lab to Factory

- Performance Comparison

Wear resistance: The treated screws work for 2000 hours in sand grains, and the wear amount is only 1/5 of the original.

Corrosion resistance: In a simulated seawater environment, the metal loss rate under the protection of the coating is reduced by 80%.

Smooth operation: The vibration value is reduced to the “silent mode” level of the original equipment.

- Typical Application Scenarios

Oilfield exploitation: The service life of sand – containing crude oil transfer pumps is extended from 8 months to 3 years.

River dredging: Coping with high – concentration sediment (30% solid content), it can operate continuously for 8000 hours without major repairs.

Chemical production: It operates stably in an extreme environment with a pH value of 2 – 12.

IV. Maintenance Tips

The “running – in period” matters:

Run with a 20% load reduction in the first 200 hours.

Regularly check the coating integrity (like the first service of a new car).

Daily monitoring:

Measure the meshing clearance monthly (a simple way: use a feeler gauge).

Judge the condition by sound: Stop the machine right away if there’s abnormal friction noise.

Repair time:

When the coating wear exceeds 1/3 of the initial thickness (about 0.04mm),

Use laser “welding repair” technology for local repair.