Stable transport of gas-rich fluids remains a critical issue in industrial operations. This is especially true for oilfields. Slug flow causes gas content to swing instantly from 0 to 100%. Shale gas extraction often deals with gas content over 80%.

Traditional pumps struggle here. Centrifugal pumps face “gas binding.” Vane pumps lose efficiency sharply. Reciprocating pumps suffer from pulsation damage.

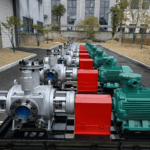

Twin screw pumps stand out. Their unique design and positive displacement principle make them ideal for these extreme conditions. Vigorous’s twin screw multiphase pumps, with targeted innovations, perform even better in complex oilfield environments.

I. How Twin Screw Pumps Handle Gas-Containing Conditions

Twin screw pumps excel in oilfield slug flow and high-gas shale scenarios. Their success comes from meshing seals and positive displacement technology. Vigorous has enhanced these features for specific needs.

1. Managing Sudden Gas Content Spikes

Twin screw pumps use high-precision gears to rotate two screws in opposite directions. A small, adjustable gap exists between their tooth surfaces.

This design works well during slug flow. It uses liquid to form a seal against high-pressure gas backflow. The gap also buffers sudden gas surges. Unlike centrifugal pumps, it won’t shut down when gas content jumps from 0 to 100%.

Vigorous’s new patented profile improves this. It optimizes meshing area and sealing paths. Combined with precise manufacturing, it reduces gas backflow during slug flow. This stabilizes efficiency when gas content fluctuates.

2. Adapting to High-Gas Shale Environments

Shale gas wellheads often have 80-100% gas content. Twin screw pumps handle this without pre-separation equipment.

Their helical design moves fluids axially. Meshing screws form sealed chambers that act like dynamic separators. These chambers compress gas gradually and push it downstream.

The pumps work well with low inlet pressure, even negative pressure. This fits perfectly with the low-pressure, high-gas conditions of shale wellheads.

3. Vigorous’s Cooling System for Slug Flow Heat

Slug flow creates intense friction. Gas rushing over screws generates 3-5 times more heat than stable flow.

Vigorous solved this with an expanded pump body. It stores cooling medium. During slug flow, this medium flows through the meshing area to absorb heat.

An external air-cooled module cools the medium before it cycles back. This keeps temperatures safe. It prevents lubricant breakdown—vital for long-term use in high-gas shale operations.

II. Key Oilfield Applications

Twin screw pumps’ stability in gas-rich conditions makes them perfect for two critical oilfield tasks.

1. Controlling Slug Flow in Oilfields

Slug flow is a common issue in oil and gas gathering. Gas-liquid interfaces fluctuate wildly, spiking gas content from 0 to 100%.

Traditional setups use large separators to buffer this. These take up space and add cost. They also risk equipment damage if separation lags.

Twin screw pumps simplify this. They connect directly to pipelines. Their positive displacement design absorbs gas fluctuations. No pre-separation is needed. This cuts complexity and reduces shutdowns from slug impacts.

2. Gathering and Transporting Shale Gas

Shale well outputs are mostly gas (80-100%). They also mix with fracturing fluids, creating gas-liquid mixtures.

Twin screw pumps handle these mixtures directly. Unlike traditional compressors, they need no pre-degassing.

A single pump combines gas-liquid transport and pressurization. This works well for scattered, space-constrained shale well sites.

III. How Twin Screw Pumps Compare to Traditional Pumps

| Equipment Type | Slug Flow Adaptability (0-100% Gas) | High-Gas Shale Stability (80-100%) | Maintenance Cycle | Typical Uses |

| Vigorous Twin Screw Pump | Stable, no impact | Efficient, sustained operation | Longer | Slug flow, shale gas gathering |

| Traditional Twin Screw Pump | Operable, moderate pressure swings | Stable operation | Medium | Standard gas-containing oilfields |

| Centrifugal Pump | High shutdown risk from gas binding | Sharp efficiency drop | — | Low-gas (≤5%) oil wells |

| Reciprocating Pump | Severe pulsation damage risk | Operable but energy-heavy | Shorter | Low-gas, low-fluctuation scenarios |

IV. Future Technical Improvements

Twin screw pump development focuses on oilfield and shale needs:

- Adaptive slug flow control: Sensors monitor gas content in real time. Screw speed and cooling adjust automatically. This boosts performance in fluctuating conditions.

- Sulfur-resistant materials: 2205 duplex stainless steel and similar alloys resist corrosion. They work well with sulfur-rich shale gases.

- Compact integration: Pumps, separators, and buffers are combined into modules. This fits better in tight shale well spaces.