In oil and gas extraction, challenges like difficult rehabilitation of water-flooded wells, complex multiphase medium transfer in coalbed methane production, and frequent equipment failures caused by slug flow have long restricted extraction efficiency. Vigorous’ specially developed Intelligent Pump Skid System for Water-Flooded Well & Coalbed Methane Extraction breaks through these bottlenecks with its core advantages of “all-condition adaptability + intelligent control,” becoming a game-changing equipment for high-difficulty extraction scenarios.

I. Core of the Product: More Than a Pump, an Integrated Solution

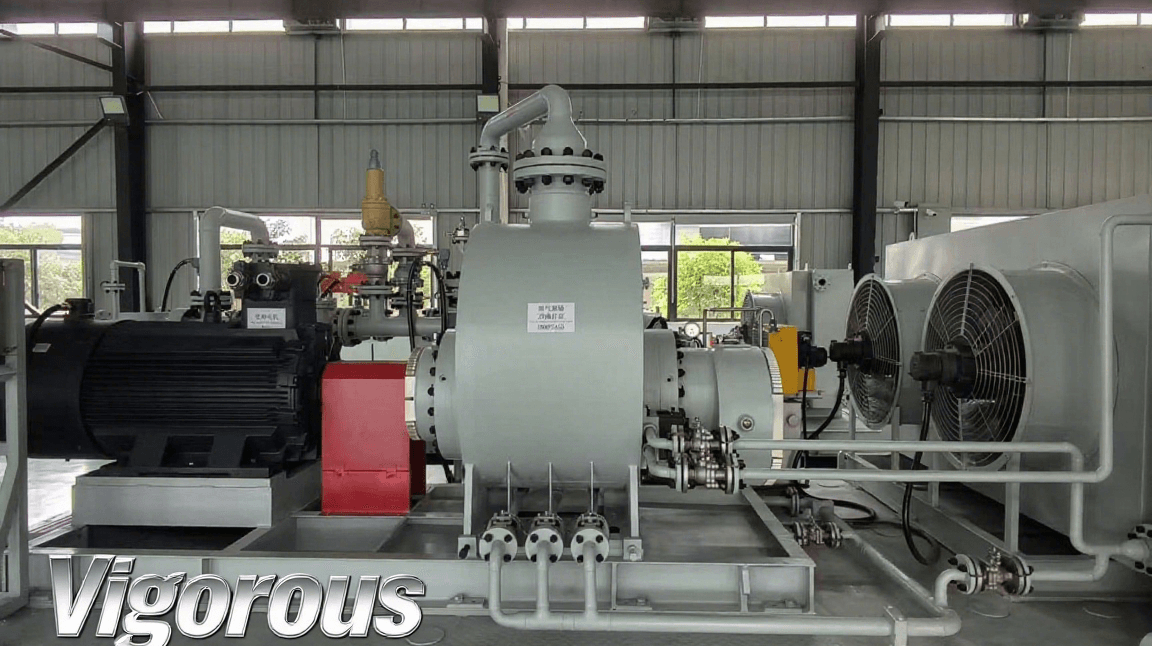

This intelligent pump skid system is designed specifically for water-flooded well rehabilitation and coalbed methane extraction, integrating “multiphase medium transfer, gas compression, and safe temperature control” in one. It eliminates the limitation of traditional equipment that can only handle single-phase media.

- Positioning: Focused on domestic oil and gas field enterprises, solving core challenges in water-flooded well rehabilitation and efficient coalbed methane extraction;

- Core Value: Achieving safe and efficient extraction under complex conditions with lower comprehensive costs (equipment procurement, installation, and maintenance), especially overcoming the industry-wide “slug flow” problem.

II. Three Core Functions: Breaking Through Extraction Bottlenecks

1. All-Condition Multiphase Medium Transfer: One Machine for Multiple Uses, No More Equipment Clutter

The main pump (model HWMPS450) easily handles any proportion of media, including “pure liquid, pure gas, gas-liquid-solid mixtures,” and even extreme conditions with 100% gas volume fraction.

This means there’s no need to equip both centrifugal pumps and compressors—one device can handle all scenarios from “pure liquid transfer” to “pure gas compression,” greatly simplifying on-site equipment layout and reducing initial investment.

2. Powerful Gas Handling + Stable Pressure Control: Dual Guarantees for Safety and Efficiency

The system features strong gas compression capacity, adapting to high gas-content extraction environments. It is also equipped with an outlet pressure balancing control system to dynamically adjust transfer pressure in real time.

Whether facing sudden gas volume fluctuations or changes in medium composition, the system maintains stable operation, reducing the risk of shutdowns caused by abnormal pressure and improving extraction safety.

3. Long-Term Slug Flow Handling: Overcoming a Global Challenge, Significant Cost Reduction

Slug flow (violent fluctuations in medium flow and composition) is one of the main causes of equipment damage and efficiency decline in oil and gas extraction.

Vigorous’ intelligent pump skid system achieves long-term stable handling of slug flow through its integrated design. Compared with traditional split equipment, the comprehensive investment (procurement + installation + maintenance) is reduced by over 30%, making continuous extraction from high-difficulty wells feasible.

III. Key Parameters: Adapting to Diverse Extraction Needs

The core parameters of the HWMPS450 main pump cover a wide range of working conditions, meeting transfer requirements of different well conditions:

- Inlet pressure: 0-10 bar

- Outlet pressure: 15-25 bar

- Displacement: 12,000-132,000 Nm³/d

- Shaft power: 260 KW

Whether it’s a small-displacement coalbed methane well with low pressure or a water-flooded well rehabilitation project with high pressure and large displacement, it can be accurately adapted.

IV. Core Equipment Modules: Dual Guarantees of Intelligence and Reliability

1. Main Pump Unit (HWMPS450): “Power Core” of Multiphase Transfer

Adopting a special cavity design, it combines the liquid transfer capacity of centrifugal pumps and the gas compression capacity of compressors, serving as the core for “all-condition adaptability.” No frequent equipment switching is needed—it seamlessly transitions from pure liquid to pure gas transfer.

2. Cooling and Temperature Control System: Avoiding High-Temperature Shutdowns, Ensuring Continuous Operation

During high gas-content, high-load operation, the pump body is prone to shutdown due to high temperatures. This system combines “automatic fluid replenishment cooling circuit + air-cooled heat exchanger”:

- Automatic fluid replenishment ensures sufficient cooling medium, and the air-cooled system quickly dissipates heat;

- Real-time temperature control keeps the pump body within a safe temperature range, reducing interruptions caused by overheating.

3. Electronic Control Module: Local + Remote Dual Control for Efficient Operation and Maintenance

- Local control cabinet: Deployed on-site, supporting manual/automatic mode switching and emergency shutdown, meeting on-site immediate operation needs;

- Remote PLC control cabinet: Communicates with the local cabinet via industrial Ethernet, enabling remote monitoring of equipment operation status, alarm reception, parameter adjustment, and integration with the oil and gas field central control system for centralized management and unmanned operation, improving operation and maintenance efficiency.

4. Drain Valve Module: Automatic Liquid Accumulation Drainage, Reducing Manual Intervention

Integrating a liquid level sensor and electric drain valve, it monitors liquid accumulation in the system in real time. When liquid accumulation reaches the set threshold, the valve automatically opens to drain, avoiding excessive accumulation that affects pump operation or causes pressure abnormalities. It ensures stable operation under low liquid level conditions, reducing manual drainage maintenance costs.

5. Oil Seal Flushing System: Extending Seal Life, Enhancing Safety

Provides continuous flushing and cooling for the pump’s mechanical seal components, delivering clean medium to the mechanical seal surface through a dedicated channel:

- Reduces seal temperature, preventing aging due to frictional overheating;

- Forms a “seal barrier” to block leakage of gas-liquid-solid mixtures, reducing failure risks.

6. Filtration System: Blocking Impurities, Protecting Core Components

Installed at the pump inlet, its core function is to intercept large particle impurities (especially sand) in the medium. The high-precision filter screen prevents large particles from entering the pump body, avoiding impeller wear and flow channel blockage, thus extending the service life of the main pump and core components and reducing maintenance frequency.

Conclusion: Simplifying High-Difficulty Extraction

Vigorous’ Intelligent Pump Skid System for Water-Flooded Well & Coalbed Methane Extraction solves core pain points in water-flooded well rehabilitation and coalbed methane extraction for oil and gas field enterprises with its three advantages: “all-condition adaptability + intelligent control + low cost.” Whether dealing with complex multiphase media or tricky slug flow, its integrated design ensures stable and efficient operation, serving as a reliable partner for high-difficulty extraction scenarios.