In fine chemical production, stable conveyance of particle-containing media demands high equipment adaptability. Xinxiang Ruifeng New Materials Co., Ltd. (hereinafter “Xinxiang Ruifeng”) faced issues like particle wear, seal accumulation, and static solidification in calcium slurry conveyance. It solved these by using Vigorous W2G series twin-screw pumps and customized solutions, ensuring continuous production.

Key Challenges in Calcium Slurry Conveyance

Xinxiang Ruifeng mainly produces new material additives. Its process requires continuous calcium slurry conveyance. The medium has these traits:

- Viscosity is around 150cSt (medium-low range). But it contains many calcium oxide particles (≤50μm in diameter), which are somewhat abrasive.

- Particles easily seep into the mechanical seal cavity with medium flow. Long-term accumulation may damage the seal, causing leaks.

- When static (e.g., during production gaps), solid particles in calcium slurry settle. This can solidify inside the pump, affecting later startups.

Traditional pumps used earlier had clear limits here:

- Screws wore quickly from particle scouring, needing replacement every 1-2 months on average.

- Mechanical seals, harmed by particle buildup, required maintenance every 2 weeks or so.

- After shutdowns over 4 hours, calcium slurry often solidified. It needed disassembly and cleaning, taking about 8 hours each time. This hurt production continuity significantly.

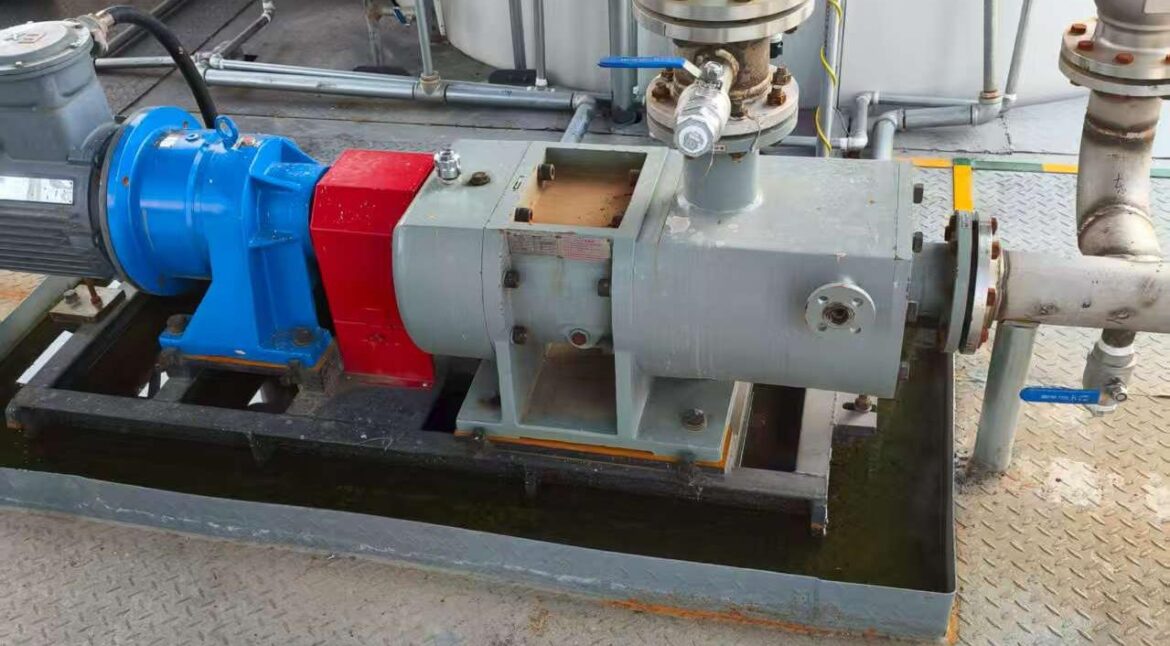

Targeted Solutions of Vigorous W2G Series

To address calcium slurry traits, Vigorous W2G series twin-screw pumps are optimized in design and operation:

- Wear-resistant design: Extending service life

W2G series screws have a coating. This increases surface hardness, boosting resistance to scouring by calcium oxide particles. - Anti-accumulation structure: Enhancing seal reliability

It uses a “top-in, rear-out” inlet/outlet layout. Medium enters from the pump top and is pushed axially to the rear outlet. This uses medium flow inertia to reduce particle residue near the mechanical seal cavity. It lowers the risk of particles wearing the seal surface. In practice, particle buildup in the seal cavity drops by ~90% vs. traditional layouts. - Anti-solidification measures: Ensuring stable startup after shutdown

A variable frequency control system is included. It supports “regular low-speed operation”: during shutdown, it runs at 30r/min for 1 minute every 2 hours. This agitates the screw to prevent calcium slurry from settling and solidifying, reducing manual cleaning needs.