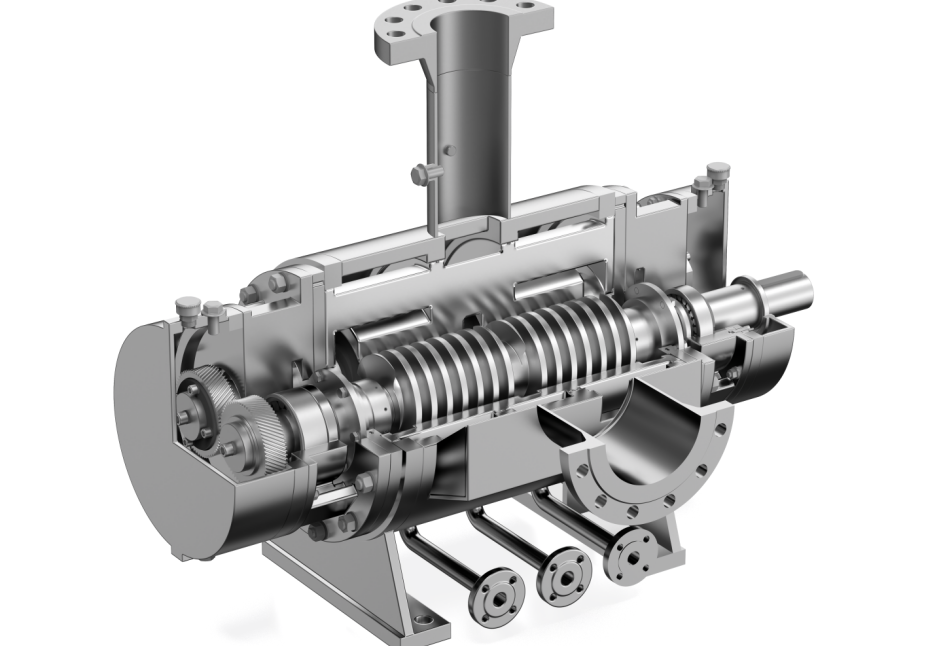

In the field of industrial fluid transfer, diverse production scenarios and medium characteristics pose various demands on transfer equipment. Our W2N series twin screw pumps are designed to meet these needs, making them ideal for complex transfer tasks with features tailored to different fluid environments.

I. Full – pressure Range, Suitable for Diverse Working Conditions

The W2N series twin – screw pumps account for the pressure differences in different applications. We’ve designed low – pressure, medium – pressure, and high – pressure models. Whether in settings with relatively low pressure needs but high flow – stability requirements or in harsh conditions demanding high – pressure transfer against large resistance, the W2N series can ensure efficient and stable fluid transfer with its precisely – matched pressure performance. This full – pressure – coverage design allows the W2N series to apply widely in various industrial environments, giving users great selection flexibility.

II. Excellent Performance, Handling Complex Media

High – water – content Media

In oilfield exploitation and related gathering and transportation systems, transporting high – water – content crude oil is a common challenge. The W2N series twin – screw pumps can effectively handle high – water – content media due to their unique screw structure and sealing design. The special helical profile and clearance fit of the screws ensure that water and other components like oil can flow stably during transfer, without affecting the pump’s normal operation, guaranteeing continuous and stable large – flow transfer.

High – gas – content Media

For fluids with high gas content, such as the mixture of associated gas and crude oil in oilfields, the W2N series twin – screw pumps show excellent gas – liquid separation and transfer capabilities. The special design inside the pump allows gas to quickly separate from the liquid after entering the pump cavity and be discharged through a specific channel, avoiding negative impacts on the pump’s performance caused by gas accumulation. Meanwhile, the impeller and screws can efficiently push the liquid to achieve smooth transfer of high – gas – content media, meeting the long – distance and large – flow transfer requirements of such complex media in oilfield gathering and transportation systems.

High – viscosity Media

When dealing with high – viscosity media, such as viscous materials in some chemical industries and high – sugar syrups in the food industry, the W2N series twin – screw pumps also perform outstandingly. Their strong power output and carefully designed screw meshing method can provide sufficient shear force and axial thrust to overcome the internal friction of high – viscosity media, ensuring the smooth flow of the media in the pump. Even when handling extremely high – viscosity media, they can maintain stable flow and pressure, ensuring the normal progress of the production process.

III. Multi – functional Applications, Optimizing Work Processes

Core Support in Oilfield Gathering and Transportation Systems

In oilfield gathering and transportation systems, the W2N series twin – screw pumps play a vital role. Their large – flow and long – distance transfer capabilities can efficiently transport mixed media such as crude oil, associated gas, and cement – containing slurry collected from various oil wells to treatment stations or storage facilities. Whether it’s the long – distance transfer from scattered wellheads to centralized treatment centers or the large – scale media transfer between different sites within a large oilfield, the W2N series can ensure the efficient operation of the gathering and transportation process with its stable and reliable performance, providing a solid guarantee for the continuity of oilfield production.

Partial Replacement of Pipeline Pigging Function

In the oilfield production process, pipeline pigging is an important maintenance task to remove residual media in pipelines and prevent blockages and corrosion. The W2N series twin – screw pumps can replace part of the pipeline pigging function to some extent. After the transfer task is done, by adjusting the pump’s operating parameters, it can reverse – transfer specific cleaning fluids or gases to purge and clean the pipeline. This function not only cuts down on the investment in additional pigging equipment but also reduces the operating pressure to some degree, improving the overall work efficiency and optimizing the oilfield production process.

IV. Comprehensive Services, Providing Media Transfer Solutions

We recognize the complexity of medium characteristics in different industries and application scenarios. Thus, we’re committed to offering users comprehensive solutions for various media transfers. Whether for conventional petrochemical media or special industrial fluids, our professional technical team can accurately select the W2N series twin – screw pumps for users according to factors such as the physical and chemical properties of the media, flow requirements, transfer distance, and pressure conditions. We also provide detailed system configuration suggestions. At the same time, we offer complete pre – sales, in – sales, and after – sales services, including equipment installation and debugging, operation training, regular maintenance, and rapid – response troubleshooting services. This ensures that users have no concerns when using the W2N series twin – screw pumps and can achieve efficient, stable, and safe media transfer.